Shimadzu LC Driver for Chromeleon™ 7 - Features

Nexera/Prominence Driver

Seamless control of Shimadzu LC

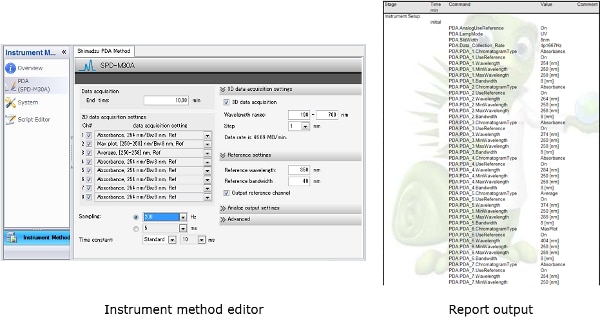

Chromeleon Instrument Method Editor screen

Shimadzu LC control parameters are set through the Chromeleon Instrument Method Editor embedded in the Chromeleon software. These parameters are stored and handled as standard Chromeleon Instrument methods so that the instruments are directly controlled from Chromeleon.

- Creation and modification of instrument methods

- Report output of instrument methods

- Direct control

- Solvent Blending

- RF Detector 4ch support

- Multi column oven (Max 4 ovens)

- System check

- Auto purging

Creation and modification of instrument methods

For Shimadzu instrument control parameters, instrument method creation and modification are possible. The screen layout for Shimadzu instrument control is the same as that of the standard Chromeleon Instrument Method Editor screen, and the created methods are stored as standard Chromeleon method. A control parameter report can be output by Chromeleon.

Instrument Method Editor screen and Example of Instrument parameter report output

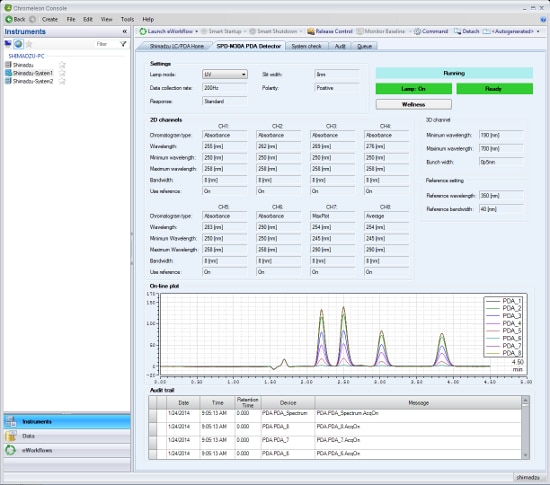

Direct control and instrument status monitoring

Lamp mode can be directly controlled from Chromeleon. Instrument status can be monitored. System check for instrument consumable parts usage are also possible.

ePanel screen

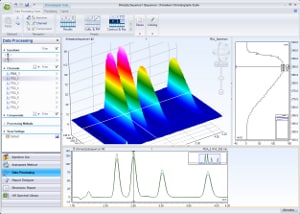

Digital data acquisition for enhanced reliability

3D data processing screen

In addition to seamless system control, the detector signal is digitally transmitted to the data system. This eliminates the necessity to add an A/D converter for analogue data acquisition, making system validation easier and more robust.

Regulatory compliance support

Full system control uses Chromeleon Instrument Method, and data processing is integrated with Chromeleon software so that the audit trail functions of Chromeleon software are fully utilized. This gives you full confidence in the compliance of the system to regulations such as GLP/GMP and US FDA 21 CFR Part 11.

Nexera series Driver

Supporting for Nexera XS inert and Nexera lite inert

It is now possible to control of Nexera XS inert system (LC-40D XSi and SIL-40C XSi) and Nexera lite inert system (LC-40i and SIL-20A/20AC) for “Shimadzu Nexera series” through Chromeleon™ Software (Chromeleon™7). Chromeleon can be used to experience the advanced features of the Nexera series, such as “Bio-inert system” that aims to suppress metal adsorption of the sample configured the sample flow path with non-metal.

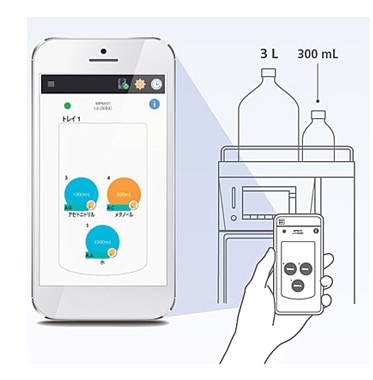

Prevent mistakes caused by running out of mobile phase

Using the MPM-40 mobile phase monitor*, it is possible to check levels of mobile phase, autosampler rinse solution etc. in real time (up to 12 bottles). Remaining volumes can be monitored from the ePanel or from a smart device. You can receive advance notifications to your PC or smart device if the mobile phase is likely to become depleted, preventing costly mistakes in analysis.

*optional

Automated pretreatment programs save labor and increase reliability

A range of pretreatment programs for the SIL-40 series includes functions for dilution, addition, co-injection, etc. Automation prevents human error and increases repeatability as well as improving overall workflow efficiency.

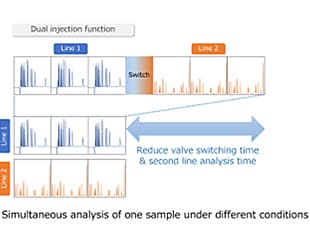

Analyze one sample in two flow paths simultaneously (dual injection)

Using the dual injection function* of the SIL-40 autosampler series, it is possible to carry out two separate simultaneous analyses on one system, saving space and time. Flow paths can be constructed for a variety of analyses – amino acids, organic acids, sugars, vitamins, positive or negative ions, etc.

* Samples used for analysis are limited to a single vial.

Advanced i-Series

Advanced Real-Time Mobile Phase Monitoring

Making sure you have sufficient mobile phase in the system—before sequence analysis—is critical to keeping your lab running smoothly. If you run out of mobile phase mid-sequence, you have to stop the sequence and take corrective action, resulting in costly workflow delays and potential loss of samples. To overcome this challenge, the Mobile Phase Monitor*1 enables real-time, gravimetric monitoring of mobile phase levels to ensure maximum uptime. Levels for mobile phase or autosampler rinse solution may be monitored in up to six containers*2. A large bottle version is also available. The containers can also be checked remotely from a smart device (PC/iOS/Android).

∗1 Optional ∗2 Monitors up to 6 liquids when using 1-liter bottles, and up to 3 liquids when using large-volume bottles (2- to 5-liter bottles).

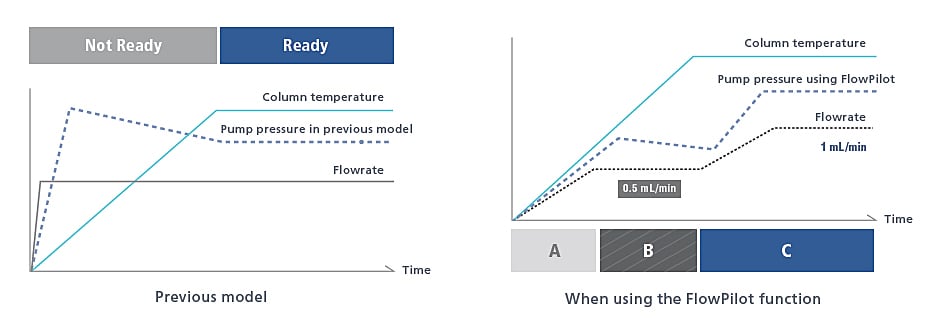

Smart Flow Control Protects Columns

UHPLC columns can be damaged by sudden pump starts and extreme gradient changes, especially true with polymeric packings. Smart Flow Control (FlowPilot) increases the flow rate gradually to the method set point according to the status of the column oven, extending the life of your columns.

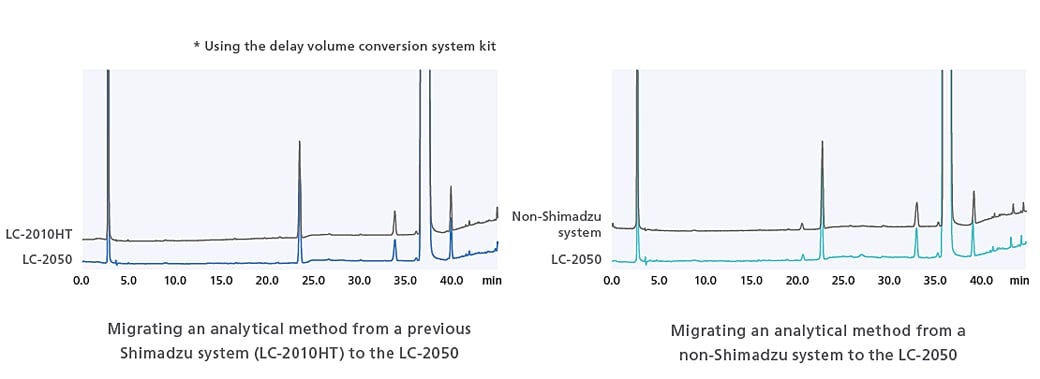

Considering Instrument Replacement and Method Migration

Migrating a test method (analytical conditions or method) from one instrument to another while obtaining the same chromatogram can be a challenging process. The i-Series is designed with the same internal system volumes as previous Shimadzu systems and competitor systems to ensure system compatibility and data reproducibility. An Analytical Condition Transfer and Optimization (ACTO) function also adjusts gradient start time automatically, so analysts can make adjustments to separations obtained by gradient analysis easily.

* The method transfer tool is not available for the method files of the other vendor software.

i-Series Driver

Easy-to-Assess Operating Status and Easy Maintenance

ePanel (Chromeleon 7.2)

The ePanel shown sample analysis window provides functions for the direct control of Shimadzu i-Series systems. It is equipped with monitoring functions to allow system operating status to be assessed at a glance, and features system checks for monitoring the usage of consumables. As a result, the software can be used for daily inspections of instruments prior to analysis, and for monitoring the operating status during analyses. Shimadzu LC control parameters are set through the instrument method editor embedded in the software. These stored parameters handled as standard method files of the software.

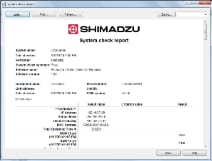

Proof That the System Always Operates in a Stable Manner

With the i-Series auto-validation function, anyone can follow a set procedure to examine solvent delivery stability, wavelength accuracy, absorbance accuracy, gradient accuracy, the presence of any drift/noise, and other parameters. In addition, a system check function automatically performs routine inspections before using the instrument. It also creates a report indicating system self-diagnostic results and a record of consumables used, such as the total solvent volume delivered by the delivery pump, the number of autosampler injections, and the number of hours the lamp has been illuminated. This makes it easy to accurately determine the operating status.

Starting auto validation

Creating system check report

Displays procedures, mobile phases, and other information necessary for validation on the screen, which allows you to perform inspections by simply following the instructions. System self-diagnostic results and a record of consumables used can be output from the i-Series Driver.