SolidSpec-3700i/3700iDUV - Features

UV-VIS-NIR Spectrophotometer

High Sensitivity

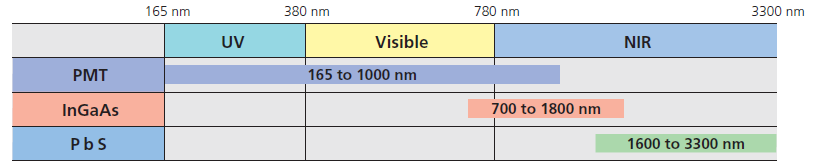

Relationship between Detectors and Measurable Range

The photomultiplier tube detector can be switched to the InGaAs detector in the range from 700 nm to 1000 nm (the default switching wavelength is 870 nm). The InGaAs detector can be switched to a PbS detector in the range from 1600 nm to 1800 nm (the default switching wavelength is 1650 nm).

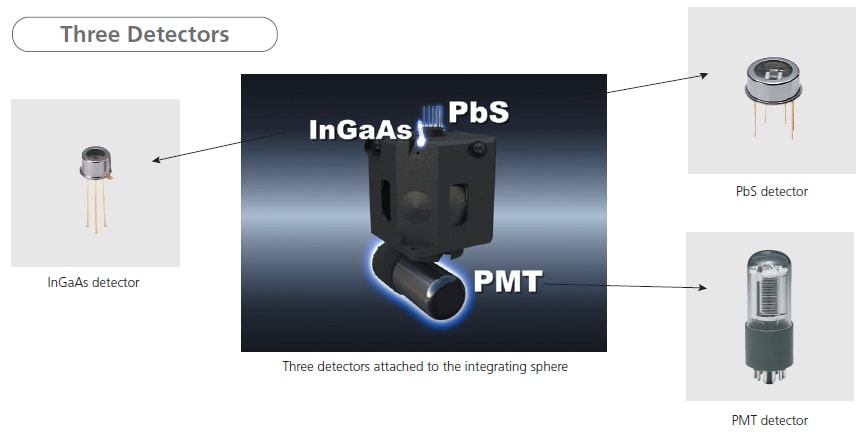

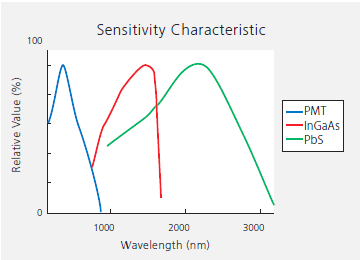

High accuracy for transmittance and reflectance is required for the measurement of optical parts. The SolidSpec-3700i/3700i DUV have three detectors which cover the range from ultraviolet to near-infrared. The sensitivity in the near-infrared region is significantly enhanced by using both InGaAs and cooled PbS detectors. Highly accurate and highly sensitive spectra are obtainable from ultraviolet to near-infrared.High accuracy for transmittance and reflectance is required for the measurement of optical parts. The SolidSpec-3700i/3700i DUV have three detectors which cover the range from ultraviolet to near-infrared. The sensitivity in the near-infrared region is significantly enhanced by using both InGaAs and cooled PbS detectors. Highly accurate and highly sensitive spectra are obtainable from ultraviolet to near-infrared.

Conventional spectrophotometers have used a photomultiplier tube detector for the ultraviolet and visible region and a PbS detector for the near-infrared region. However, neither detector has much sensitivity near the detector switchover, preventing high sensitivity measurement in this range. The SolidSpec-3700i/3700i DUV make it possible to take high sensitivity measurements in the switchover range by using an InGaAs detector as shown in the figure on the left.

Wide Measurement Wavelength Range (SolidSpec-3700i DUV)

The development of precise laser machining using an ultraviolet laser such as an ArF excimer laser enhances the requirement for transmittance or reflectance measurements of optical parts in the deep ultraviolet region. The SolidSpec-3700i DUV(note1) enables measurement in the range of 175 nm to 2600 nm(note2) with an integrating sphere and the range of 165 nm to 3300 nm(note3) by mounting the optional Direct Detection Unit DUV. With this additional unit, the wide range from deep ultraviolet to near-infrared is now measurable.

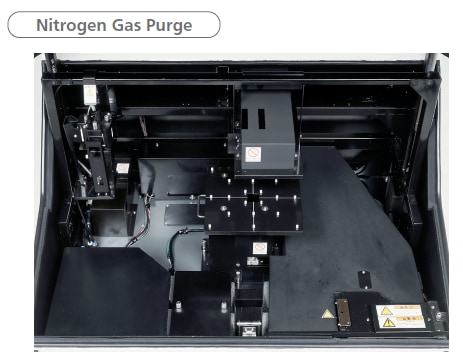

Oxygen molecules in the atmosphere absorb ultraviolet light under 190 nm. Nitrogen gas purging for both the optical and the sample compartment is required to remove the interfering oxygen molecules. Since the SolidSpec-3700i DUV has purge inlets for each compartment, efficient nitrogen gas purge is possible so that the time required for purging after sample replacement is reduced, and high sensitivity with lower stray light in the deep UV region is achieved.

Materials which do not absorb deep ultraviolet light are required to be used as the window material for the detector and the material for the inside of the integrating sphere to enable performance in the deep ultraviolet region. The SolidSpec-3700i DUV uses a PMT detector with fused silica as the window material and an integrating sphere with resin that has highly reflective characteristics in the deep ultraviolet region as the inside material.

Note1) In order to measure the range below 190 nm with the SolidSpec-3700i DUV, nitrogen gas purge is required to remove interference from oxygen molecules inside the SolidSpec-3700i DUV.

Note2) The measurable range for SolidSpec-3700i is 240 nm to 2600 nm.

Note3) The measurable range for SolidSpec-3700i with the optional Direct Detection Unit is 190 nm to 3300 nm.

Large Sample Compartment Accommodates a Wide Variety of Samples.

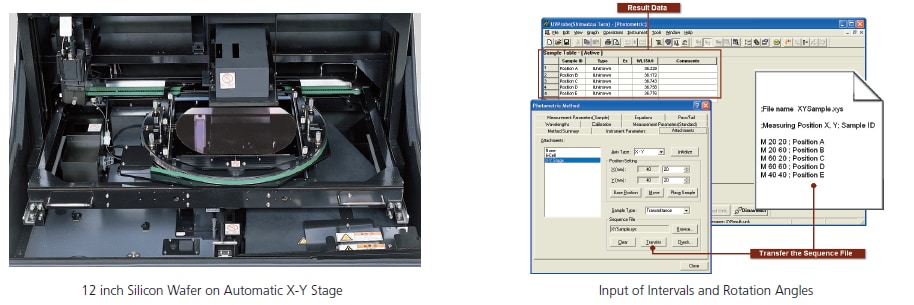

The SolidSpec-3700i & 3700i DUV have large sample compartments which allow large samples to be measured without sample destruction. Their internal dimensions are 900W × 700D × 350H mm. A sample maximum of 700W × 560D × 40H mm can be set in the sample compartment and an entire sample area of 12 inches or 310 × 310 mm is measurable by mounting the Automatic X-Y stage (option). The vertical optical path makes it possible to perform transmission or reflectance measurements of large samples.

Large Sample Compartment

A sample of 700W × 560D mm is set in the sample compartment.

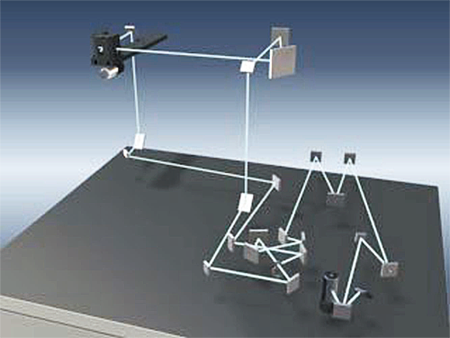

Three Dimensional Optical Path

The three-dimensional optical path enables non-destructive measurement of large samples, without having to cut them smaller. In the optical path of previous models, light only traveled horizontally, but the new models include a three-dimensional optical path (U.S. patent 6583872) with light also traveling in the vertical direction. Samples can be placed horizontally, which makes it easier to place large samples.

A wide variety of accessories, such as absolute specular reflectance attachments and relative specular reflectance attachments created for the SolidSpec-3700i/3700i DUV; expand the application range. Automatic measurements can be performed with the optional Automatic X-Y Stage by inputting the intervals and the rotation angles for the sample.

Automatic Measurement

Automatic X-Y Stage (Option)

The Automatic X-Y Stage developed for the SolidSpec-3700i/3700i DUV enables automatic measurements for the points specified in advance while maintaining the nitrogen gas purge.

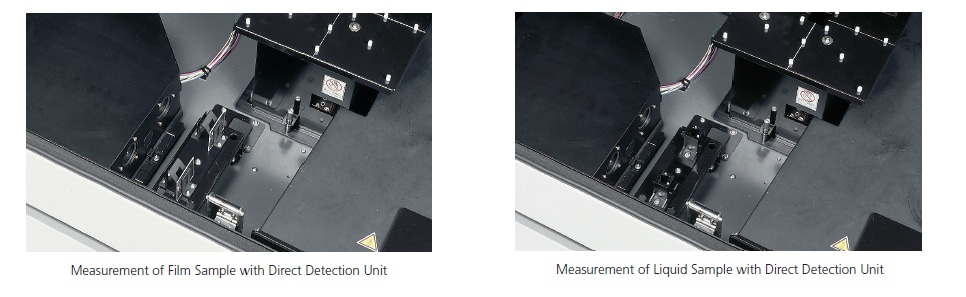

Direct Measurement of Liquid Samples and Solid Samples without Integrating Sphere

Direct Detection Unit (Option)

The SolidSpec-3700i/3700i DUV measure samples with an integrating sphere as the standard detection system. However, some samples require measurement without using an integrating sphere. The Direct Detection Unit was created for just such instances. By mounting the Direct Detection Unit (DDU-DUV) in the SolidSpec-3700i DUV, measurements down to 165nm(note) are possible. Measurements with the Direct cDetection Unit can be performed simply by switching a mirror.

Note) In order to measure below 190 nm with SolidSpec-3700i DUV, nitrogen gas purging is required to remove interfering oxygen molecules inside of the SolidSpec-3700i DUV.The measurable range for the SolidSpec-3700i with the optional Direct Detection Unit is 190 nm to 3300 nm.