OPTIC-4

Multimode Inlet for Gas Chromatograph-Mass Spectrometer

High-Performance Multimode Inlet

A Next-Generation Inlet Accommodating a Variety of Sample Forms

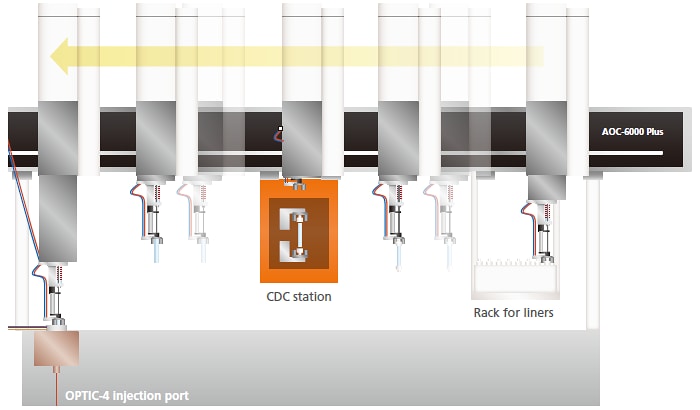

Equipped with injection modes capable of accommodating a wide range of sample forms, the OPTIC-4 is the ultimate inlet in GC-MS sample injection systems. Attaching the OPTIC-4 to the AOC-6000 Plus draws out its very best performance.

The wide range of injection modes offered by the OPTIC-4 multimode inlet makes it possible to accommodate many different sample forms. So, in addition to split/splitless injections, many other analyses, such as the pyrolysis analysis of solid samples and the thermal desorption analysis of odor components, can be performed.

Various liners

Simplifying Pretreatment—DMI

(Difficult Matrix Introduction)

With DMI, a microvial containing the sample is inserted in the liner, and the liner is then heated at the injection port before analyzing the sample. By adjusting the temperature of the injection port, non-volatile impurity components are left remaining in the microvial, enabling GC/MS measurements to be performed with a minimal amount of pretreatment.

After Trapping/Concentration Using MonoTrap™,

Thermal Desorption Provides High-Sensitivity Analysis

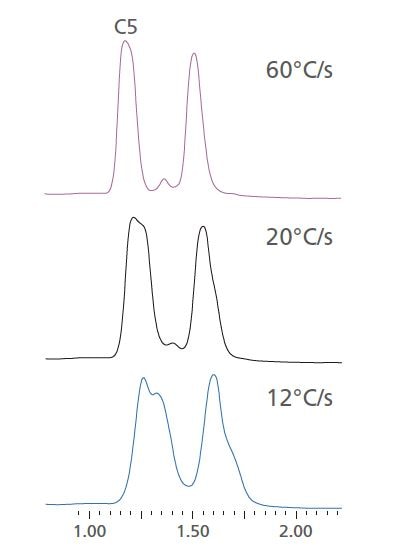

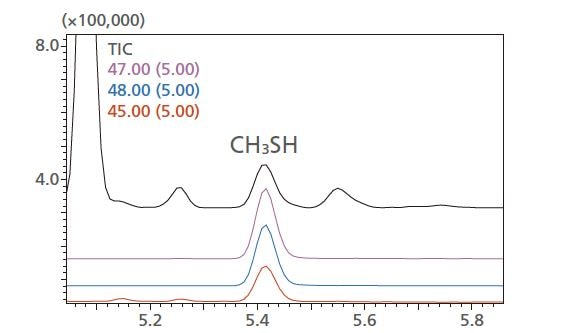

By using the MonoTrap*, which has a silica monolith structure and a high trapping efficiency, to trap volatile components in the sample, then using the OPTIC-4 for thermal desorption, analyses requiring higher sensitivity can be performed. Moreover, the high-speed heating function provides for rapid desorption of the trapped components, which results in acquisition of sharper peaks.

The liner placed in the rack, after removing its caps at the CDC station, is installed in the OPTIC-4 injection port.

* For further information on the MonoTrap, refer to the website of GL Sciences, Inc.

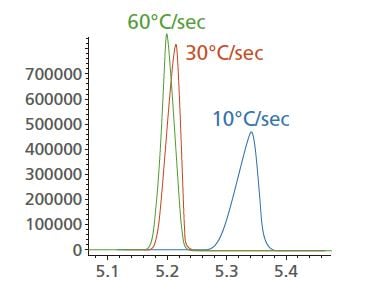

Sharper Peaks, Enhanced Separation

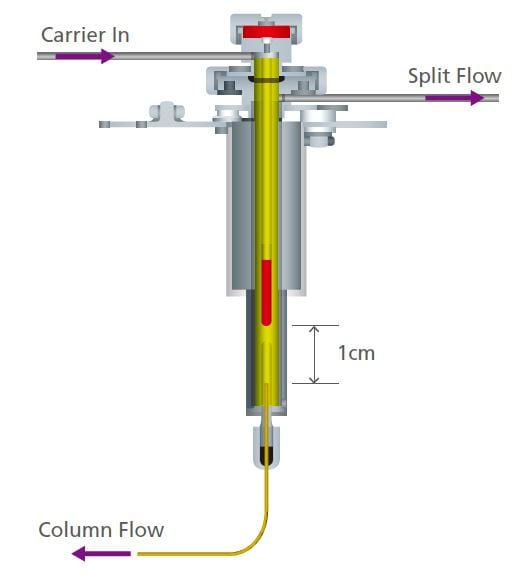

Due to a sample introduction path of only 1 cm, and the adoption of a high-speed heating system capable of 60 °C /s, sharper peaks are realized.

TD mode

There is only 1 cm between the sample and the tip of the analysis column. For this reason, the system is ideal for analysis of compounds with high adsorptivity or degradability.

MonoTrap used to analyze methanethiol in parmesan cheese

OPTIC-4 injection port

Peaks are made sharper by attaching a cryo-trap (option) to the GC oven. Samples trapped by the cryo-trap are heated rapidly, up to 60 °C/s, so the development of bands is kept to a minimum.

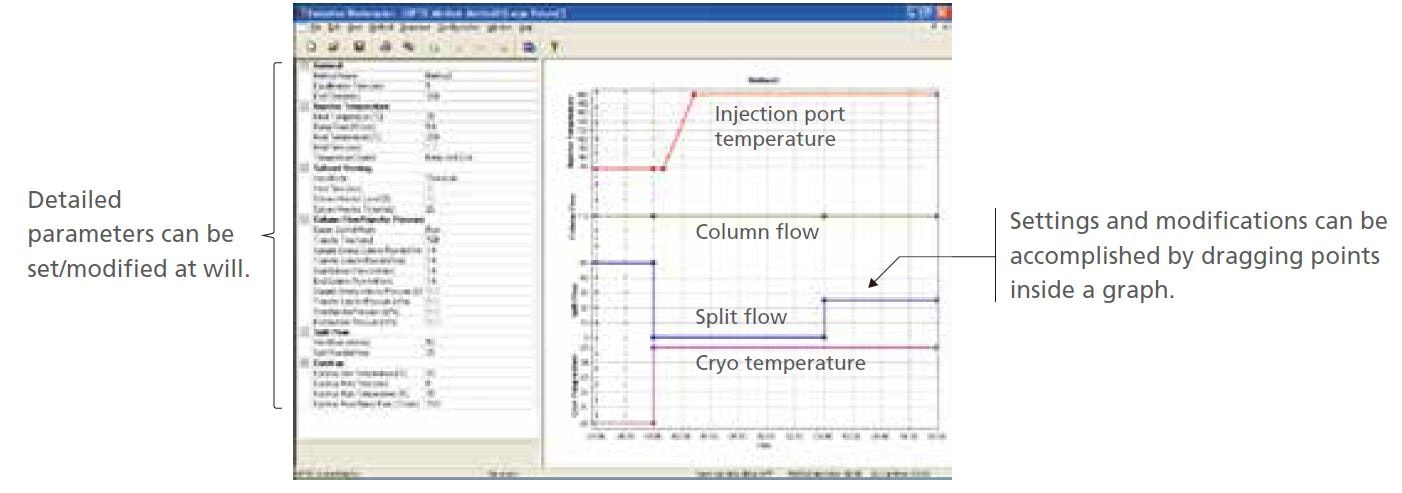

Intuitive Operation Using Dedicated Evolution Workstation Software

The dedicated Evolution Workstation software for the OPTIC-4 displays analysis conditions in a time chart for intuitive grasping and modification, enabling easy formulation of conditions. Optimization is easy, since methods accommodating various injection modes have been included.

Large volume injection method

Wide Variety of Injection Modes

The various injection modes allow analysis of many different sample forms.

| Liner | Sample Introduction Method | Application Examples |

| DMI | Thermal extraction | Content of 1,4-dioxane in shampoo |

| MonoTrap TD | Thermal desorption | Odor from Clothing |

| MonoTrap TD | Thermal desorption | Odor from product |

| DMI | Pyrolysis | Pyrolysis of resin |

| DMI | Reactive Pyrolysis | Reactive Pyrolysis of Resin |

| Solid adsorption agent (TD) | Thermal desorption | Atmospheric gas in automobile |

| DMI | Thermal extraction | Reactive Pyrolysis of Resin |

| MonoTrap TD | Thermal desorption | Aroma from Food Products |

News & Events

-

Shimadzu (Asia Pacific) And SepSolve Analytical Announce Strategic Collaboration To Deliver Cutting-Edge GCxGC–TOF MS Solutions

-

A Day With Nobel Laureate: Nobel Insights Into Shimadzu’s Mass Spectrometry (MS) Technologies

-

Four Shimadzu Analytical and Measuring Instruments Win the Internationally Recognized “Red Dot Design Award 2024”