Analysis of Components in Lithium-Ion Battery with Shimadzu's Leading Technologies and Solutions

The lithium-ion (Li-ion) rechargeable battery is a relatively new type of battery that was first used in the early 1990s. With their high voltage and high energy density, these batteries are widely used for consumer electronics applications, such as mobile phones and laptop computers. Due to enhanced consumer concerns for the environment and fuel savings, the automobile industry has also been developing these batteries for hybrid vehicle (HV) and electric vehicle (EV) applications, which should lead to enhanced output, efficiency, and performance. As a leading manufacturer of a broad range of analytical and testing instruments, Shimadzu provides a variety of solutions that contribute to research, development, and quality control of rechargeable li-ion batteries as they become more widely used in consumer electronics and eco-cars.

Download a copy of Shimadzu's Lithium Ion Batteries: Analytical Solutions here for more details on lithium-ion battery testing, and keep reading to learn more about its fundamentals.

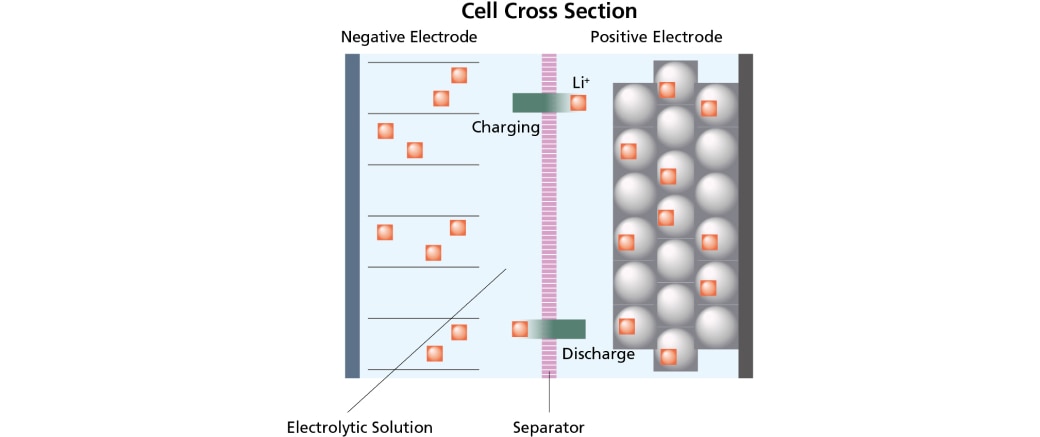

Components of a Lithium-Ion Battery

Lithium-ion batteries consist of four major components, namely the positive electrode, a negative electrode, an electrolytic solution, and a separator. When a battery is charged, lithium ions escape from the positive electrode made of metal oxide, pass through the electrolytic solution, reach the negative electrode, and accumulate. During discharge, lithium ions emitted from the negative electrode move to the positive electrode through the electrolytic solution. This enables an electric current to flow to the outside.

Read on to learn how lithium-ion batteries contribute to a future of cleaner energy. Alternatively, get the PDF for comprehensive and straightforward insights.

Multifaceted Solutions for Improving Performance and Quality of Lithium-Ion Secondary Batteries

In the field of transport equipment, which accounts for approximately 20% of CO2 emissions, there is a strong demand for expanding the use of electric vehicles with little environmental load, such as electric vehicles (EV) and hybrid vehicles (HEV and PHEV). Achieving this goal will require both a reduction in the cost of lithium-ion secondary batteries, which account for a large portion of car body prices, and an improvement in performance, such as extending the travel distance and shortening the charging time. In addition, issues related to high-energy density, long life, and safety must be resolved. Research institutes around the world are making all-out efforts in research and development and demonstration projects to address these issues.

Shimadzu provides a diverse array of analytical and measuring equipment for research and development to material property evaluation, product quality control, and degradation analysis. These technologies will allow researchers and manufacturers around the world to address issues related to lithium-ion secondary batteries and improve performance and quality.

An Overview of the Lithium-Ion Batteries Components

Electrolytes and Emission Gas

Electrolyte solutions have played a key role in lithium-ion batteries (LiB) acting as a lithium-ion transporter between the cathode and anode. High purity and battery-grade electrolyte solutions are therefore crucial for the performance of lithium-ion batteries.

The most common LiB electrolytes are derived from lithium salt solutions, such as LiPF6 in non-aqueous solvents, such as alkyl carbonates. The performance of electrolyte solutions can be further modified with suitable additives.

Gas chromatography coupled with mass spectrometry will make it possible to carry out a quantitative and qualitative analysis of electrolytes and the degradation products of lithium batteries.

This technique is based on the separation of compounds according to their affinity with a stationary phase present in a column and a mobile phase (gas) that will allow the circulation of compounds in this column. The analytes will be more or less retained according to their affinity with the stationary phase of the column.

Liquid chromatography (HPLC) coupled to a refractometric detector can be used for analyzing the quality of carbonate-type electrolyte solutions while ion chromatography (IC) can also be employed to analyze electrolyte degradation and quantify fluoride ions.

Electrodes and Components

Lithium batteries' electrodes are composed of metallic materials, like lithium cobalt oxide cathodes and graphite anodes, underscoring the significance of managing the purity of these components.

In order to analyze the purity of the metallic materials, it is possible to track the concentration of carbon, in the metal powders, as a marker of organic pollution. Measuring the carbon concentration in metal powders is done simply by using a total organic carbon analyser coupled with a solid sampling module.

This system makes it possible to degrade the sample and oxidize the carbon present by heating to 900°C. The carbon is converted into CO2, detected and quantified by an NDIR (non-dispersive infrared) detector. This technique makes it possible to obtain precise quantities of carbon present in a sample.

Separators

Battery separators are integral for sustaining the performance and safety of batteries. Nonetheless, like all other battery components, inadequate monitoring or regulation of separators can lead to adverse effects. To evaluate the resistance of separators, a universal testing machine (UTM) can be used for perforation measurements under controlled temperature to check the robustness of the separators.

The measurement will make it possible to obtain the data curves which represent the forces necessary to be applied as a function of the temperature to degrade the separators.

Download Our Handbook Now

Lithium-ion batteries, along with their fundamental building blocks, lithium-ion cells, represent a pivotal innovation in the field of electronics. Widely utilized across various products, from portable electronic devices to electric cars, these batteries have transformed the way we power and interact with technology.

Our handbook on Lithium-Ion Batteries further explores the analysis of the individual components and evaluates how these analyses can help to achieve better battery performance.