PDA-7000 - Features

Optical Emission Spectrometer

Vacuum Monochromator

The monochromator must be held in a vacuum or in a gas-replacement atmosphere to avoid effects due to the absorption of spectral lines such as C, P, S, B, and N by atmospheric oxygen.

Shimadzu adopts a vacuum monochromator that is resistant to the effects of temperature fluctuations. It is installed in a temperature-controlled monochromator chamber to achieve extremely stable measurements.

New Spark Stand Enhances Stability

Spark Stand

The structure and materials of the conventional spark stand have been upgraded to considerably enhance analysis accuracy for high-concentration elements (stainless steel and aluminum alloy). It accepts large sample plates, offers greater ease of handling, and enhances durability.

Further, selecting the optional stand water-cooling kit (see page 12) restricts the spark stand temperature rise due to electrical discharge during continuous analysis, thereby enhancing the stability of the measured values.

User-friendly Software

The software was designed for process analysis, with due consideration of the situation at sites where metals analysis is conducted. After the instrument is started, only one action is required to enable measurement and allow simple process analysis.

Simply enter the required information in sequence to easily create the analysis information.

Superbly Functional Software Supports Your Operation

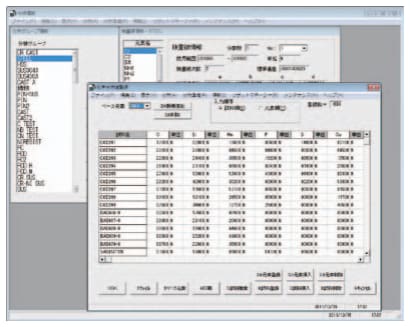

Analysis Information Screen

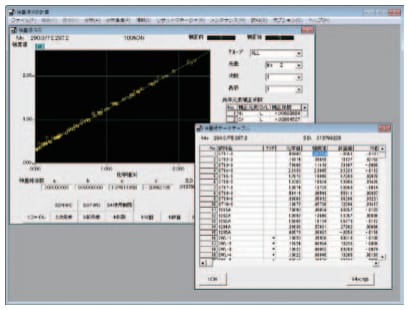

Calibration Curve Screen

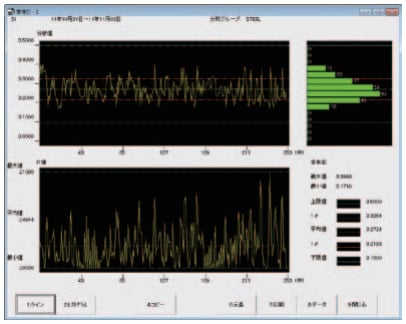

Control Chart

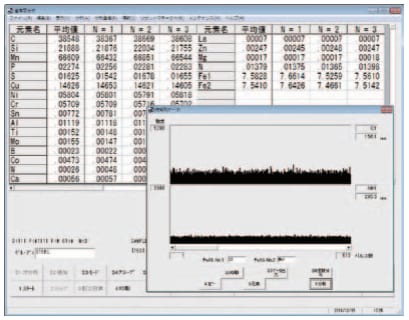

Content Analysis Screen

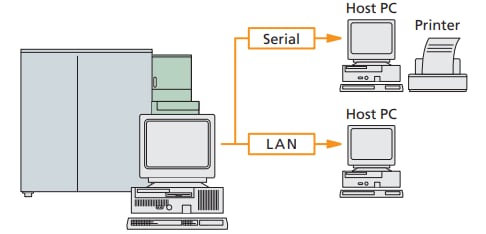

Analysis data can be transferred to host computers and printer.

Analysis Information and results can be used in commercial database/spreadsheet software.

High-sensitivity Analysis of Nitrogen in Steel

Due to the significant effects of nitrogen on the mechanical properties of steel, the rapid measurement of nitrogen during the manufacturing process is highly desirable.

The PDA-7000 has recently been developed to replace gas analyzers for in-furnace analysis. It achieves a lower detectable limit of 5ppm. This instrument reduces sampling operations and shortens analysis times. Additionally, it eliminates sample defects and enhances yields through its ability to control nitrogen in cast iron.

Sensitive Analysis of Trace Elements in Steel

The establishment of manufacturing technologies for high-purity iron demands process control at lower trace levels of elements, including C, P, and S.

The PDA-7000 meets these needs by permitting quick and easy ppm-level analysis by time-resolution PDA photometry.

Elimination of Contamination Effects

Replaceable units in the new spark stand eliminate to the maximum degree effects from high-content sample analysis during trace-element analysis.

This effectively eliminates effects from the analysis of aluminum alloys when high-purity aluminum is analyzed, for example.

Electrode Cleaning Extends Electrode Life approx. 10 Times

Electrode life is increased by approximately ten times by adopting brushing for electrode regeneration in addition to conventional reversed discharge. Naturally, the convenient reversed discharge is also provided as standard.

To enhance long-term stability, the optional automatic electrode-cleaning unit (page 12) can be selected to keep the counter electrode clean by automatically brushing away adhering sample deposits. The attached automatic sample retainer mechanism allows everyone to set samples under identical conditions.

New Chassis Case Design offers Superb Environmental Resistance

The newly designed chassis case enhances environmental resistance.

The monochromator is made of materials resistant to the effects of temperature fluctuations and is installed in a constant-temperature chamber.

The popular compact design is retained. The chassis case can be mounted against the wall to save space. The functional design allows maintenance access from the front.

The chassis case design offers greater freedom in analysis laboratory layout.

Select Optimal Discharge Conditions to Suit Analysis Range and Elements

Several separate discharge types are available for each analyzed element: high-energy discharge, spark discharge for excellent reproducibility, and arc-like spark discharge for high sensitivity. A combination of these can also be selected to set the optimal discharge conditions.

Used with time-resolution photometry, these settings achieve high analysis accuracy.

The addition of the optional small-sample analysis kit (page 12) permits measurements on 0.01mm-thick samples and small-diameter samples.

Extremely Simple Operation

Simply mount a sample in the spark stand, enter the sample number, and press the start button to display the analysis results on the screen in just over ten seconds. (The actual analysis time depends on the analysis conditions.)

The analysis data can be easily converted for flexible processing by commercial software.

Energy-Saving Design to Reduce Running Cost

While the instrument is not in analysis mode, argon gas flow is reduced to one-tenth compared with conventional model.

Energy-saving design contributes lower running cost.