TRAPEZIUMX-V - Features

Operation Software for Material Testing

Select from Five Software Programs

Single Software

This software is used to perform typical single-direction tests. It enables performing tensile, compression, and bending testing.

Cycle Software

This software enables performing endurance testing and other tests that involve repeated application of test forces.

Control Software

This software enables creating a user-specified testing machine movement routine. It allows tests to be performed in which foam rubber is compressed and held repeatedly.

Texture Software

This software enables measuring the properties (texture) of foodstuffs and pharmaceuticals. Special data processing results, including mastication, jelly strength, and adhesion, can be obtained.

Spring Software

This software enables the testing of springs. Both the characteristic values specific to springs and the spring height and length can be measured.

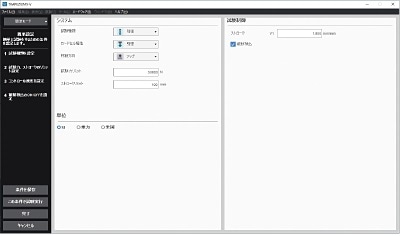

Visual Wizard Provides Guidance for Setting Parameters with Confidence

Software Wizard for Specifying Parameters for Sample and Data Processing

- Parameter settings can be specified while viewing the overall sequence using the test parameter wizard.

- Easy-to-understand illustrations are used in windows for specifying parameters for test control, samples, and data processing. Specifying settings is now very easy.

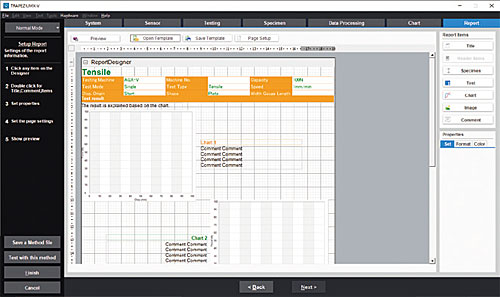

Better, More Flexible Reporting

- Report Designer with Flexible Layout

You can create reports with test results, graphs, photos, logos, and more.

Items on the report can be arranged and sized as desired.

The font, color, and border of each item can also be set finely. - Output reports in PDF, Microsoft Word®, Excel®, and HTML formats

Reports created in the Report Designer can be output in a variety of formats.

Customize reports the way you want with familiar software.

Worry-free Features Ensure Data Reliability

More Reliable Data Management by User Control, Operational Logs, and Automatic Data Transfer Functions

- With the user login function, limits on functionality can be established for each user.

- If the network transmission function is used, the test results can be transferred automatically to a host system when the test is finished. The software is also capable of reorganizing the data in the file to transfer.

- The software has an event log and an operational log function.

- The size of the sample can be read in from electronic calipers, and the sample name can be read in from a bar-code reader.

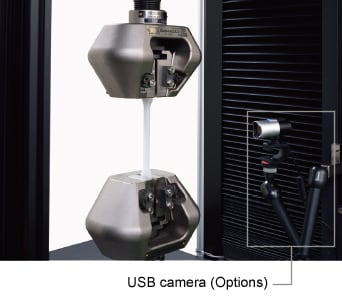

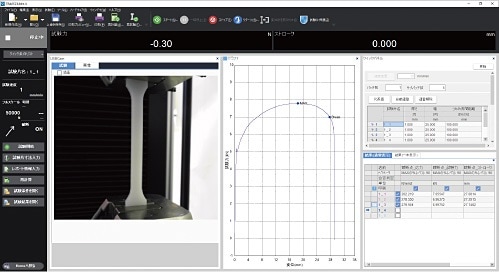

USB Camera Function Provides Evidence of Testing

- Using a camera with a USB connection, videos interlinked with the start and end of tests can be recorded.

- Samples can be observed with a video playback function interlinked to the stress-strain curve.

- Still images excised from the video can be pasted into reports as test evidence.

Support for Difficult Settings

Easy Conditions Settings Mode Ensures that Anyone Can Start Testing Immediately

The absolute minimum number of settings is gathered together, so tests can be implemented with no confusion. After the test, the test results can be analyzed in detail using the recalculation functions.

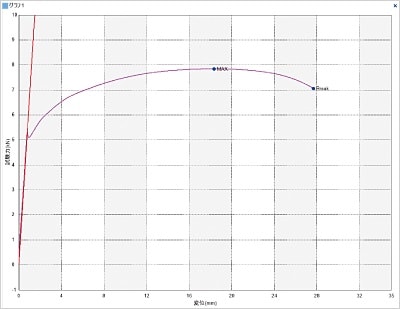

Automatic Calculation of the Elastic Modulus with No Parameters Required

The elastic modulus, an important evaluative index for material testing, is calculated automatically with no parameter settings required. Even unknown materials with unknown characteristics can be tested with confidence.

The logic behind the calculations is based on methods recommended in ISO6892-1 (2016) Annex A.

Convenient Features Save Time and Effort

Off-Line Analysis Function Makes Efficient Use of Time Even During Testing

A second instance of the software can be started up off-line during testing. Even in the midst of long tests, the conditions for the next test can be created, and previous results can be analyzed, which saves time.

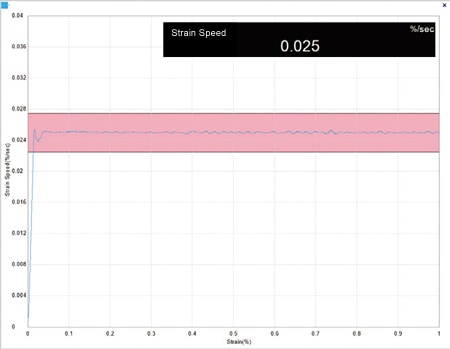

Quickly Verify Test Control with High-Speed Sensors

Data on strain rates, stress rates and other speeds can be displayed while being calculated in real time. Data that had been determined manually after testing can be calculated automatically, and users can check at a glance that the control accuracy prescribed by regulations is being satisfied.

Web Applications Enable Users to Check Results from Remote Locations

Data on strain rates, stress rates and other speeds can be displayed while being calculated in real time. Data that had been determined manually after testing can be calculated automatically, and users can check at a glance that the control accuracy prescribed by regulations is being satisfied.