Nexera UC Prep - Features

Semi-Preparative Supercritical Fluid Chromatography System

Unique technology achieves higher recovery rates

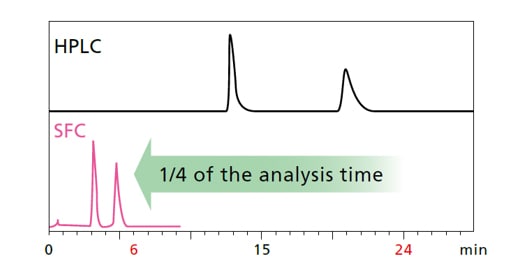

SFC shortens analysis times

Due to the low viscosity and high diffusivity of supercritical CO2, column back pressure for supercritical fluid chromatography supercritical fluid chromatography (SFC) is low even at high flow rates which enables faster analysis without sacrificing column efficiency. This allows significantly shorter analysis times than HPLC.

In purification using SFC, the target compounds are recovered in high concentrations in an organic solvent, which saves time not only during analysis, but also during post-run processing after preparative tasks are complete. The Nexera™ UC Prep maximizes fractionation output with its high recovery rates and ability to carry out continuous preparative work that further shortens the user's waiting time.

High recovery rates

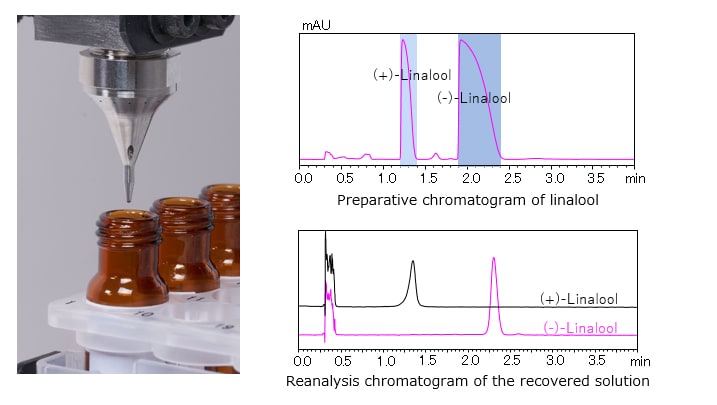

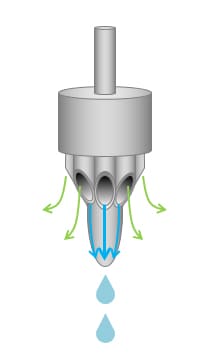

In preparative SFC, one factor that results in lower recovery rates is increased scattering of the eluent when the CO2 returns from a supercritical to a gaseous state. The Nexera UC Prep's patented gas-liquid separator, the LotusStream separator, successfully reduces sample dispersion and carryover, while also achieving high recovery rates. These high recovery rates can be obtained regardless of flow rate or modifier concentration, even for volatile compounds such as the fragrance linalool.

| Equipment | Recovery rate |

| Conventional separator | 78.0% |

| LotusStream Separator | 96.7% |

LotusStream separator (patented technology)

Decreases flow rate without increasing the pipe diameter by splitting flow through multiple channels. The CO2 is discharged externally while the liquid travels along the column and drips directly into the collection vessel without dispersing or spattering the eluate.

Direct fractionation into vials

Direct fractionation into 96-well plate

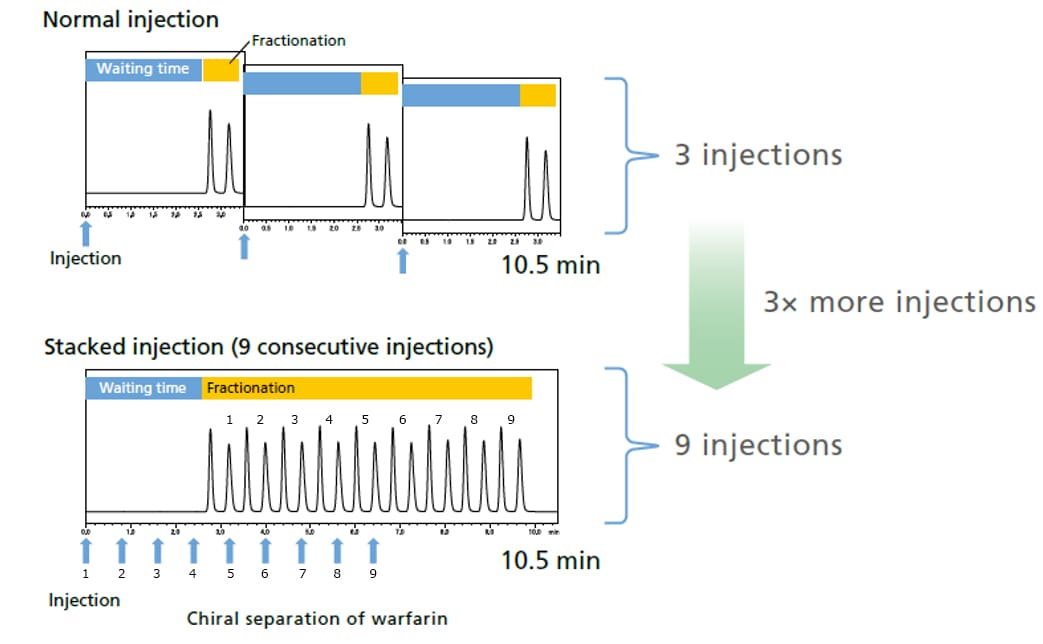

Stacked injection function eliminates waiting time

Normal injection wastes time between peak elutions. Using the Nexera UC Prep’s stacked injection function, samples can be injected continuously without any waiting time, enabling more samples to be processed. Settings for this function can be specified easily in the dedicated software Prep Solution.

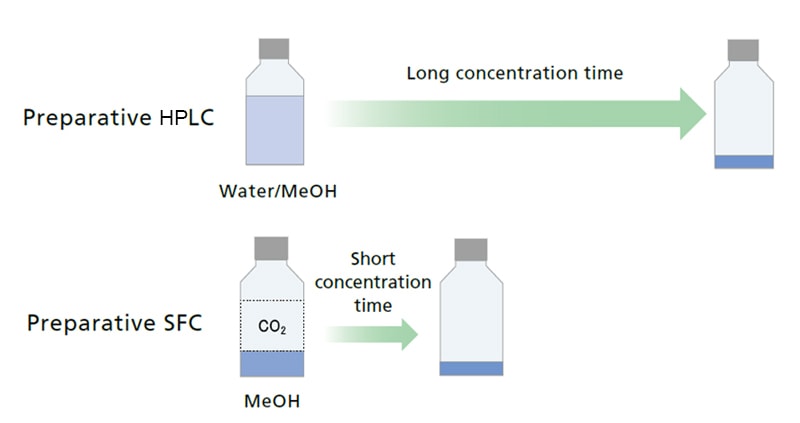

Simple post-run processing

Because most of the mobile phase is vaporized supercritical CO2, only the organic solvent (modifier) added to change the polarity of the mobile phase remains after preparative work. Since there is no water content in the recovery fraction, the concentration time is significantly shorter.

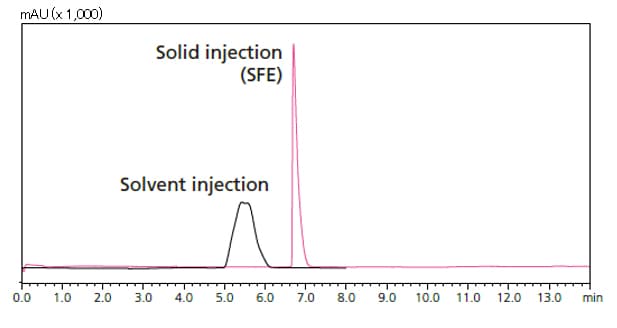

Solid autosamplers for increasing loading capacity

More of the target compound can be fractionated at once by loading a large volume. However, this can sometimes lead to poor separation and broad peak shapes because of sample solvent effects. By performing fractionation with the on-line SFE-SFC, solid samples can be enclosed in an extraction vessel and extracted directly without dissolving in a solvent. A good peak shape prevents simultaneous elution of contaminants and improves the purity of the target component.

Chromatogram of ketoprofen (5 mg) loaded

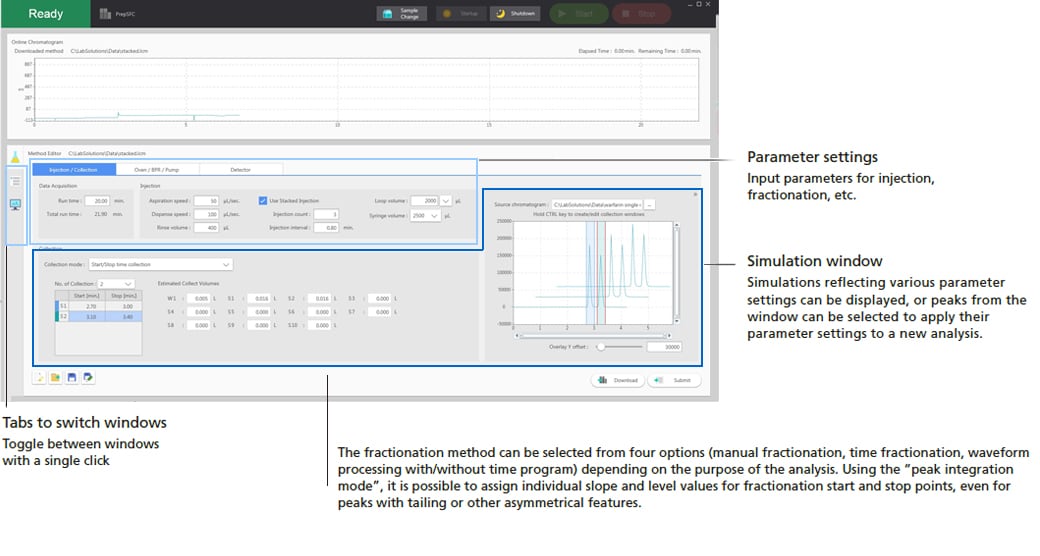

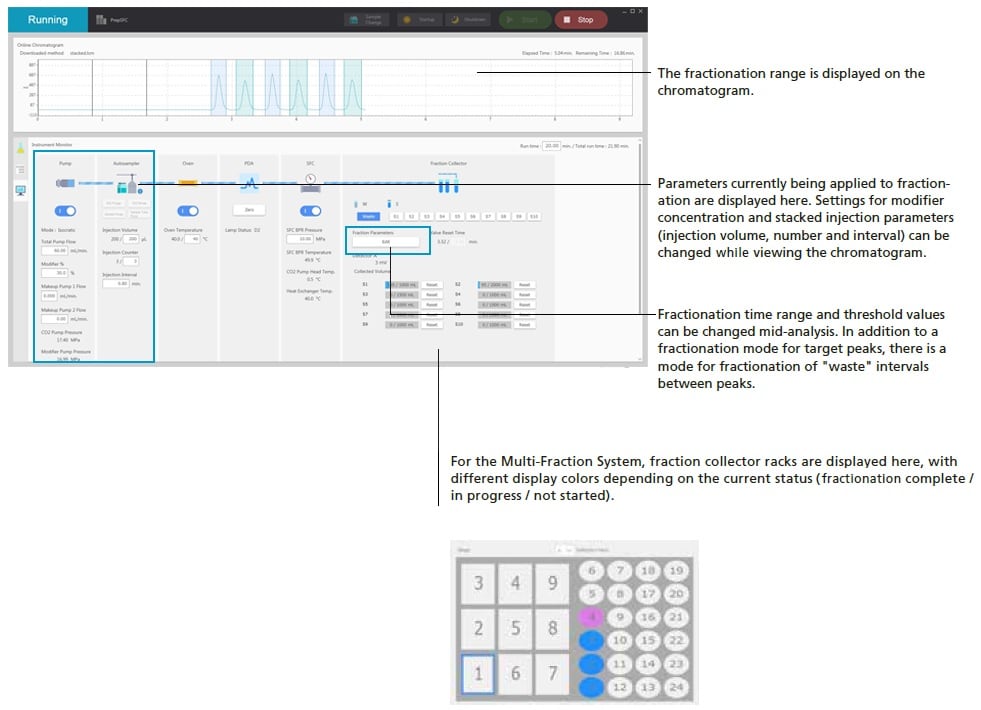

Prep Solutions enables a seamless preparative workflow

The dedicated software, Prep Solution, ensures that it is simple to scale up from an analytical to a preparative workflow, and makes it easy to configure parameter settings. It greatly increases the efficiency of preparative workflows.

Easy to understand even for first-time users

The parameter settings in Prep Solution have been kept as concise and intuitive as possible, so that all users can operate the system with minimal training. This also avoids the risk of wasting samples through human error.

A trial analysis, or scouting run, prior to fractionation confirms component peak shapes and retention times. Analysis can be started by simply inputting basic parameters in the three onscreen tabs.

The chromatogram obtained from the single analysis can be displayed in the simulation window, so that the collection start and stop times for each fraction can be selected with just a few mouse clicks. These settings can be applied to methods automatically.

Samples are fractionated based on the user-selected parameters. The fraction range is displayed on the chromatogram, which can be checked in real time.

Parameter settings for fractionation and injection can be adjusted during stacked injection ("on-the-fly" function).

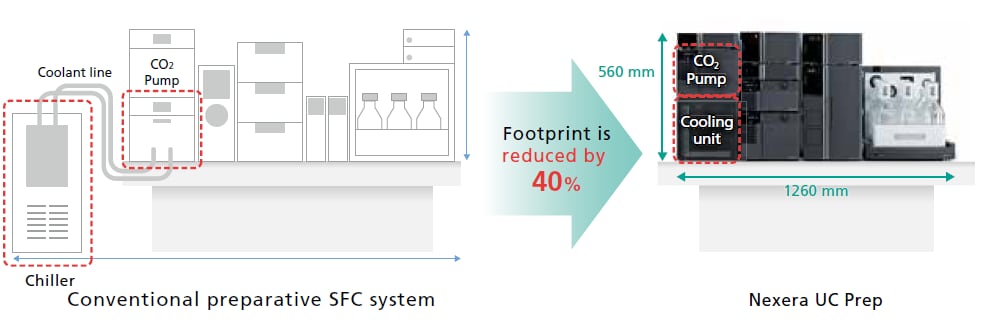

Compact, benchtop design

This space-saving benchtop model includes a carbon dioxide pump that does not require an external chiller (cooling system for cooling system for heat generated when pumping CO2 at high flow rates). In addition, one unit can handle a wide range of flow rates, lowering installation costs.

Benchtop system that can be installed anywhere

Usually a chiller is required to cool the solvent delivery pump when pumping CO2 at high flow rates. However, the Nexera UC Prep features a compressor-type cooling unit, reducing the size of the system and allowing it to be installed anywhere. Its footprint is equivalent to an analytical scale SFC system.

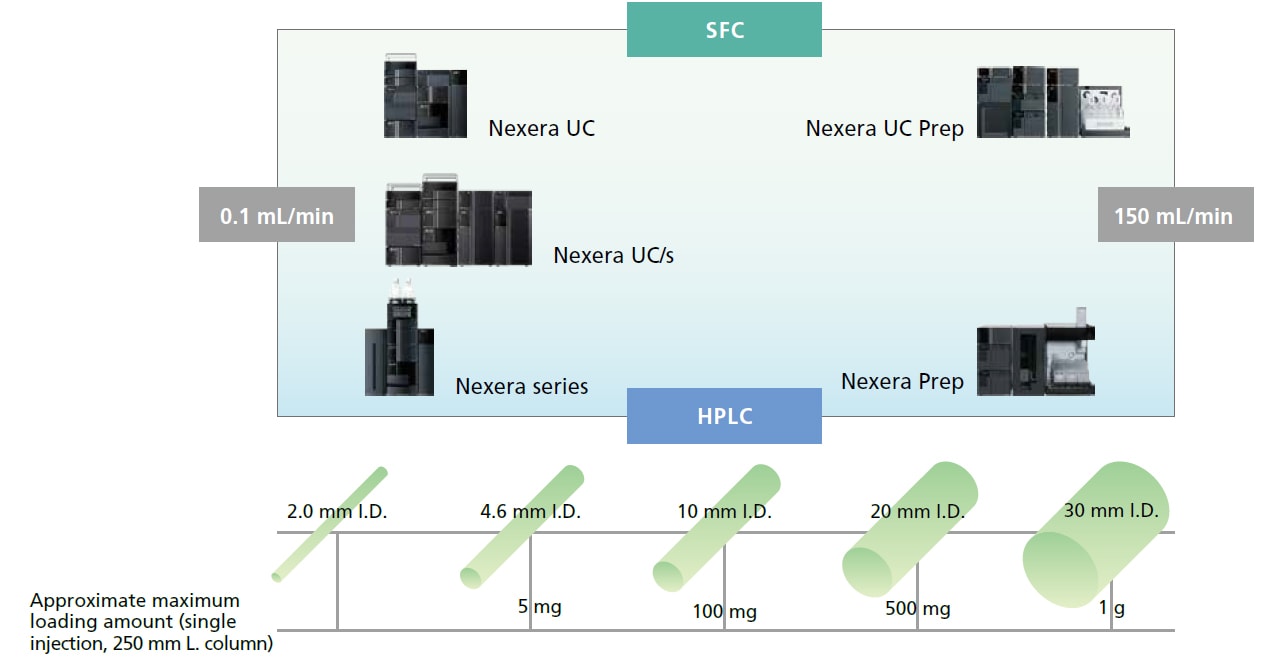

Wide range of flow rates available

In a single system, the Nexera UC Prep can handle ow rates from 10 to 150 mL/min for fractionation of a range of sample sizes, from a few hundred mg up to a few grams. Shimadzu provides various preparative systems, such as Nexera UC/s, which can perform SFC analysis and UHPLC analysis using a single system. The system corresponding to the application can be selected.

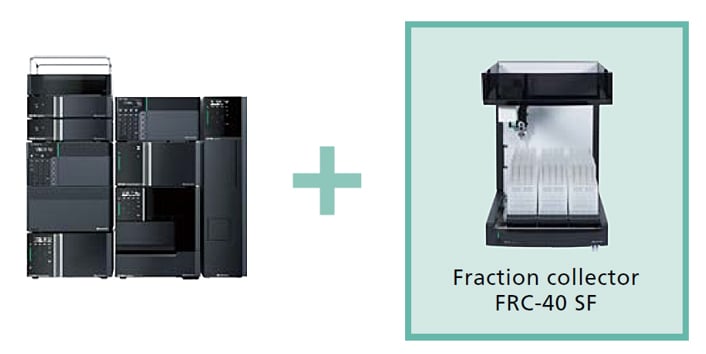

Add fractionation capabilities to the analytical SFC system

By adding a fraction collector to the analytical scale SFC system, it is possible to upgrade to a small-volume preparative system. A complete workflow can be carried out seamlessly on one system, from method development to fractionation.

Shimadzu’s unique LotusStream separator allows fractionation of small volumes, even into vessels such as 1.5 mL vials, without scattering of the solvent.

Fully automated on-line extraction and fractionation

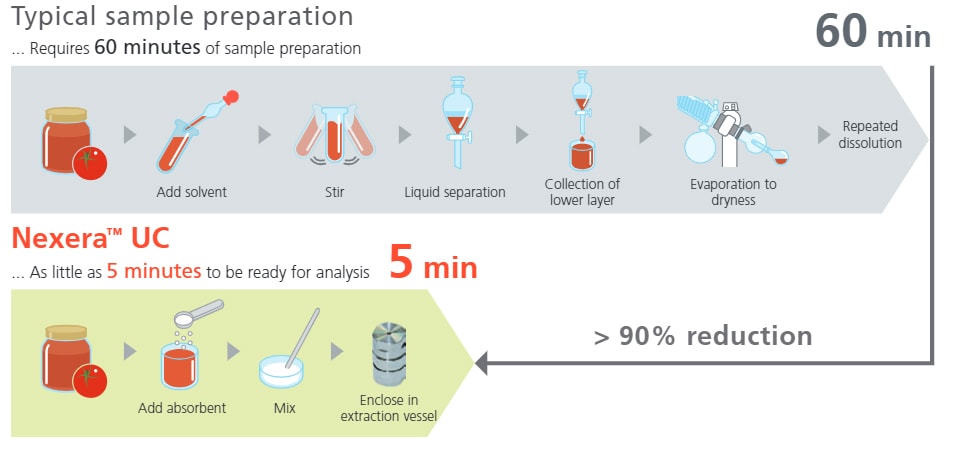

Nexera UC on-line supercritical fluid extraction (SFE) , SFC is a revolutionary system that combines on-line SFE, SFC and, fraction collector in a single flow. Target compounds are extracted from solid samples and then automatically transferred to SFC/MS so that no human intervention is required. The Nexera UC on-line SFE–SFC system reduces sample preparation time and acquires highly accurate data. Preparation can be carried out by connecting a fraction collector.

On-line Automation of the extraction and analysis of functional components in natural products

Target compounds are extracted from solid samples and then automatically transferred to SFC so that no human intervention is required. In the case of tomato paste, after preparing for analysis in as little as 5 minutes, extraction, separation, and detection of lycopene are automatically carried out. In addition to a shorter sample preparation, Nexera UC can automate the extraction, analysis, and fractionation process with the addition of a fraction collector.

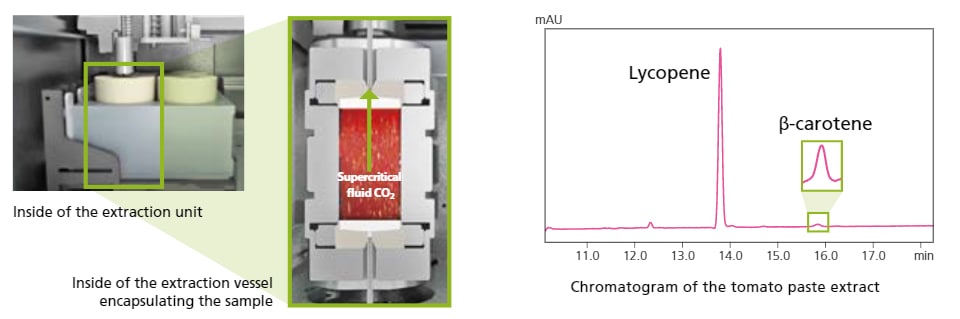

On-line SFE–SFC technology achieves a high recovery rate

After placing the extraction vessel in position on the SFE unit and starting analysis in LabSolutions™ (analysis software), extraction and purification are performed seamlessly.

Online SFE–SFC enables the functional component “lycopene” to be automatically extracted from tomato paste. The amount of extracted lycopene is equivalent to the value indicated on the product packaging.

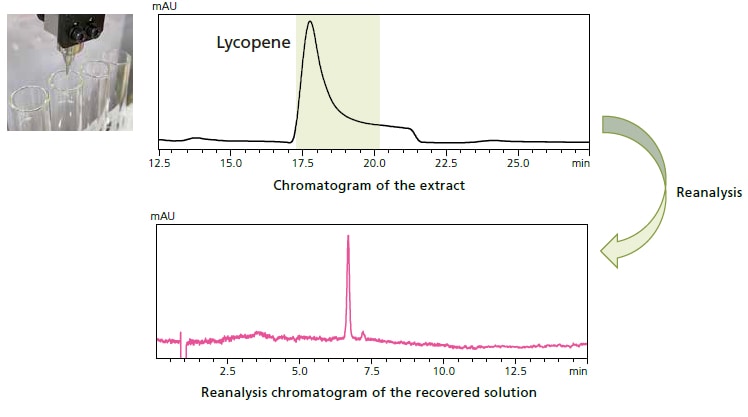

Maximize fractionation output and labor-savings

On-line extraction, separation, and fractionation are possible by connecting a fraction collector at the end of the detector. Furthermore, scale-up from analytical to preparative scale increases the volume of fractions. The Nexera UC Prep SFE unit (maximum ow rate: 150 mL/min) with a preparative column enables high-volume extraction. On-line SFE-SFC can automatically run the extraction, purification and fractionation continuously day or night. The target compounds are recovered in high concentrations in an organic solvent, saving time during post-run processing after preparative tasks are complete.

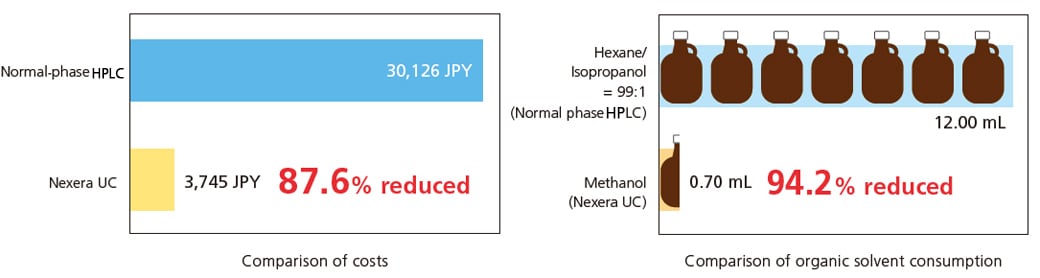

Nexera UC reduces environmental impact

Comparison of costs and consumption of organic solvent for a single analysis by conventional normal-phase LC vs. SFC is shown below. By using SFC, the total cost of analysis is reduced by 87.6% and the consumption of organic solvent is reduced by 94.2%.