Nexis GC-2030 - Features

Gas Chromatograph

Designed with the Analyst in Mind

Delivers the Best Performance Regardless of Location

Laboratories today require faster and higher performance analysis. The Nexis GC-2030 features Analytical Intelligence to help achieve these goals. Clean Pilot, a system conformity test, and LabSolutions™ can provide an automated workflow together with remote operation and monitoring from instrument startup to analysis completion. Automated workflows incorporate the work-style habits of experienced analysts. The result is reliable data collected over extended periods and higher productivity.

- Information at Your Fingertips

Analysts will benefit from the touch panel interface, which features clear graphics that display information instantly whenever needed. The user-friendly interface leaves the operator free to focus on obtaining optimal analytical results. -

Main settings controllable via the touch panel on the GC unit

- Analytical conditions

- Self-diagnostics

- Automatic carrier gas leak check

- Chromatogram display

-

Making Routine Analysis More Convenient

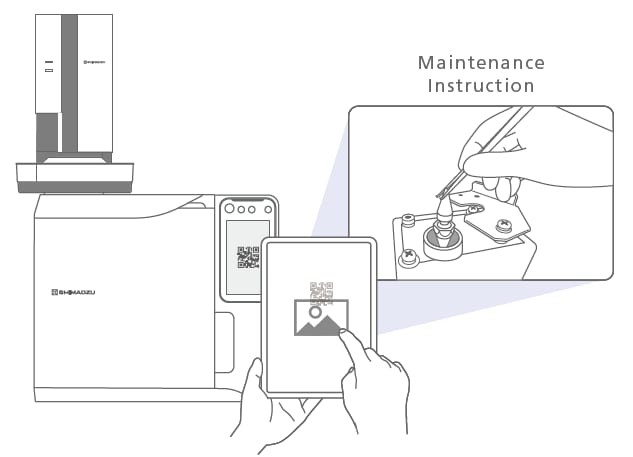

2D Code Navigation

Reading a 2D code shown on the touch panel directs the user to a website with instructional videos on maintenance. This feature helps improve system availability and increases efficiency. -

Tool-free Column Installation

ClickTek™ connectors* make tool-free column installation a snap. The click sensation felt when finished attaching the column provides a more reliable connection and ensures a better seal under all operating conditions. In addition, a light has been installed inside the oven to brightly illuminate the area at hand, easing the burden on the operator when attaching columns.

* optional

One-Touch Inlet Maintenance

The injection port can be opened or closed without tools by simply sliding the ClickTek lever. Replace the insert, slide the lever and feel the click for a leak-free install every time.

ClickTek Connector

ClickTek Nut

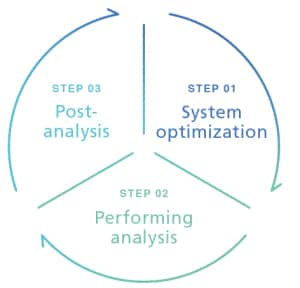

Automating the Procedures of Experienced Analysts

-

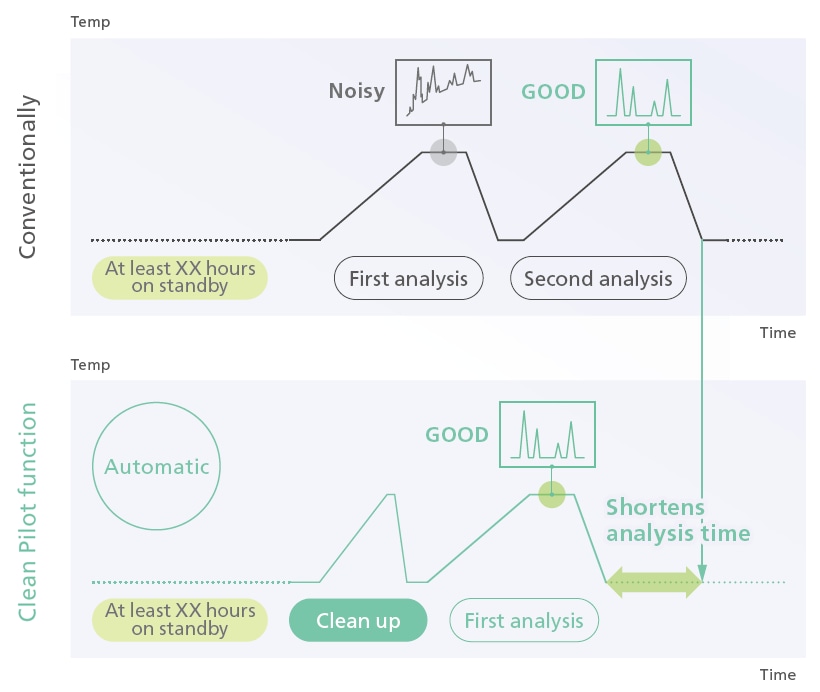

Clean Pilot Function

During typical GC startup and batch analyses, in order to dispose of impurities remaining within the column, the operator has to implement conditioning by manually raising the oven temperature. Using the Clean Pilot function, conditioning is performed automatically, leading to more stable analytical results while easing the burden of lab work.

-

Remote Operations and Monitoring

-

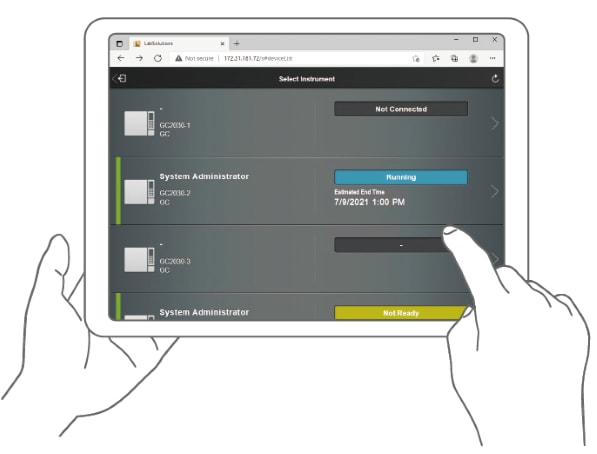

LabSolutions Direct Accommodates Remote Work

LabSolutions Direct is a remote access tool used to control or monitor GC systems via a simple user interface on a commercially available smartphone or tablet. Consequently, analyses can be performed while monitoring the status of instruments from locations away from the laboratory.

-

Directly access a GC unit in the laboratory from

Directly access a GC unit in the laboratory from

a smartphone or tablet computer

-

Perform these main settings via a smart device

• Starting and stopping the GC

• Starting and stopping analysis

• Monitoring chromatograms

• Checking instrument status

• Browsing analysis results in PDF format

• Checking the status of multiple instruments -

Best-in-class* Sensitivity and Reproducibility

Achieves Exceptional Reproducibility

Nexis GC-2030 provides the best-in-class analysis accuracy. Shimadzu's new AOC-30 auto-injector automates the analysis, reduces an operator's workload, and enables continuous analysis with a high degree of accuracy that cannot be achieved by manual operation. In addition, an advanced flow controller (AFC) included in the CPU supports carrier gas constant linear velocity control, constant flowrate control, constant pressure control, and various other control modes and achieves exceptionally high reproducibility for ultra-high-speed and ultra-high-precision control modes.

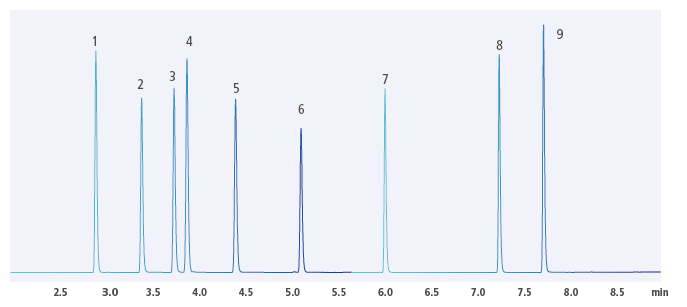

Chromatogram Overdraw (n=10)

Chromatogram Overdraw (n=10)-

1 n-Decane 0.162 6 Methyl nonanoate 0.157

2 n-Octyl alcohol 0.163 7 Methyl decanoate 0.141

3 2,6-Dimethylphenol 0.160 8 Methyl dodecanoate 0.180

4 n-Undecane 0.145 9 Dicyclohexylamine 0.208

5 2,6-Dimethylaniline 0.149

* As of July 2021, according to a Shimadzu survey.

Simultaneously Control Up to Three Injection Units and Four Detectors

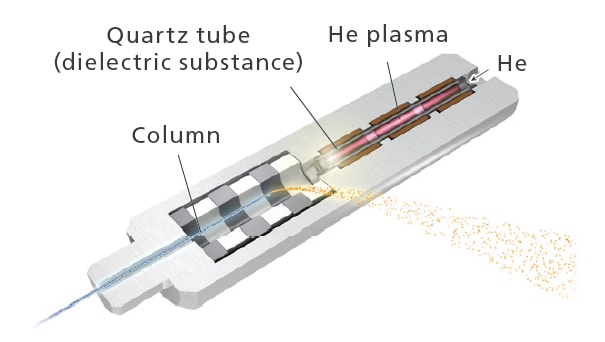

- Barrier Discharge Ionization Detector (BID)

The barrier discharge ionization detector (BID-2030) is a universal detector that offers high-sensitivity analysis by using a low-frequency dielectric barrier discharge plasma for ionization. The BID generates helium (He) plasma by applying a high voltage to a quartz glass tube. The light energy from the He plasma then ionizes the target components and the ions are collected and output as peaks using a collection electrode. A wide variety of compounds other than He and neon (Ne) are detected with high sensitivity. -

Barrier Discharge Ionization Detector

(BID-2030)

Exceptional Versatility and Productivity

-

Simultaneously Control Up to Three Injection Units and Four Detectors

The most optimized system can be selected depending on the purpose of analysis and target components. Four detectors can be controlled simultaneously using LabSolutions.*

In addition, both capillary and packed columns can be attached, so multiple analysis methods can be run with a single GC unit, saving on laboratory space.

* The number of detectors installed depends on the type of detector. -

AOC™-30+HS-20 NX (Trap model) + GCMS-QP™2020 NX

-

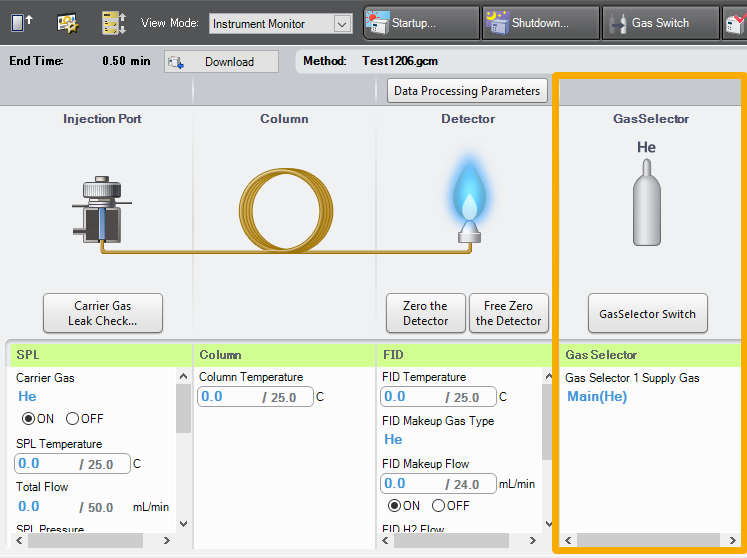

Switching Carrier Gases via a Gas Selector

Changing the type of carrier gas involves a great deal of work, including the replacement of the piping and gas filters. With the gas selector (optional), the carrier gas can be switched via the software, so different analyses can be performed while easily switching the carrier gas. -

Switching Gas with LabSolution GC