TOC-4200 - Options

On-line TOC Analyzer

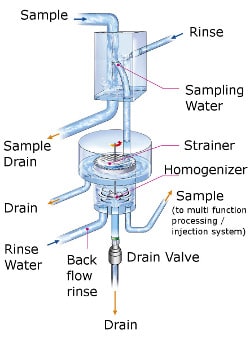

Multi-Stream Suspended Solids Sampling Unit

Click to movie (16,828KB)

- Used for samples with comparatively high suspended solids levels.

- It can treat samples in up to six flow lines.

- Separating the sampling unit and pretreatment unit reduces the number of parts requiring maintenance.

- Incorporates a homogenizer equipped with a strainer.

- The strainer is the most easily contaminated part. It is in contact with liquids during sampling only.

It is rinsed with rinse water immediately after sampling, reducing problems with slime and algae build-up. - Required sample flow rate: Approx. 10 L/min

- A low-flow (LF) model has been newly added to the product lineup.

(Required sample flow rate: 1 to 2 L/min)

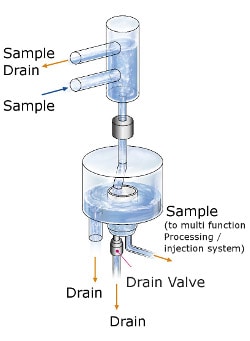

Multi-Stream Sample Switching Unit

- Used for samples without suspended solid.

- It can treat samples in up to six flow lines

- Assuming measurements of purified water, a water sampler is installed to minimize exposure of the sample to air.

- Required sample flow rate: 1 to 3 L/min

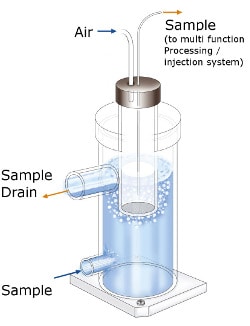

Backwash Strainer Sampling Unit

Click to movie (5,347KB)

- This unit is an adjustment bath used for samples with low suspended solids levels.

- Offers automatic backwashing using air.

- A germicide installed in the air line suppresses blockage of the strainer by microorganisms and growth of slime and algae in the bath.

- Required sample flow rate: 1 to 3 L/min

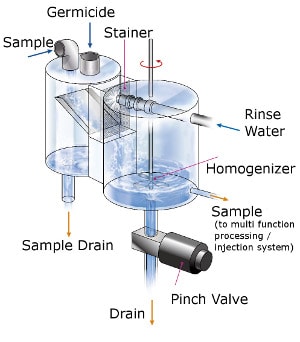

Single Stream Suspended Solids Sampling Unit

Click to movie (10,298KB)

- Used for samples with comparatively high suspended solids levels.

- This Sampling unit is electrically driven. It requires no air supply.

- After dirt is removed by the strainer, the homogenizer pulverizes and homogenizes the suspended solids to obtain stable measured values.

- The strainer is the most easily contaminated part. It is in contact with liquids during sampling only. It is rinsed with rinse water immediately after sampling, reducing problems with slime and algae build-up.

- A germicide is installed to effectively suppress slime and algae growth.

- Required sample flow rate: 2 to 5 L/min