Hydrogen and Fuel Cells

Hydrogen and Fuel Cells

Hydrogen can be produced by various industrial processes including refining of natural gas and electrolysis of water. Hydrogen is of interest as a clean energy source that emits only water as a byproduct when used. As a result, hydrogen is being used as a reactant in fuel cells to generate electricity, as a combustion fuel to generate thermal energy, or as a storage medium for intermittent sources of energy, such as wind and solar power.

Shimadzu can provide a comprehensive suite of instruments used for hydrogen quality control, analysis of catalysts and water for electrolysis, and evaluation of fuel cells and their components.

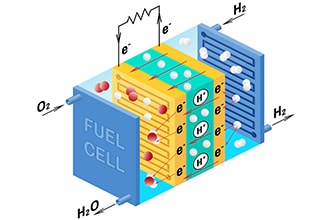

Fuel cells are devices that generate electricity through the reaction of hydrogen and oxygen, and are an extremely clean energy source as they only emit water. It is highly efficient and produces only water, no harmful substances, and is attracting attention as a product that has the potential to greatly contribute to solving both energy and environmental problems. Particularly in recent years, full-scale spread is expected in the automobile, housing, and mobile device fields.

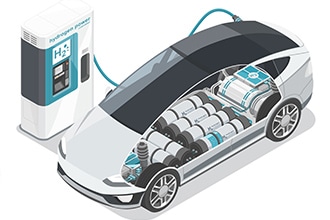

Impurities in hydrogen production affect subsequent industrial processes. Consequently, strict purity standards have been defined for hydrogen used in fuel cells (ISO 14687-2023). This is because if hydrogen contains carbon monoxide, sulfur components, etc., the catalyst of the fuel cell will be damaged. The hydrogen fuel standard for FCVs (ISO 14687 Type II Grade D) defines many items to be controlled, and Shimadzu analytical instruments can play a role in analyzing these items.

Hydrogen carriers are a method of efficiently storing and transporting hydrogen, which is inefficient in storage and long-distance transportation in its gaseous state, by converting it into a liquid or hydrogen compound. There are two methods: liquefying or compressing hydrogen to increase hydrogen density, and converting it into another substance with high hydrogen density and easy handling (organic hydride, ammonia, formic acid) and extracting hydrogen from that substance for use.

In addition to extracting and using hydrogen, it may also include burning it as is, such as with ammonia, to use hydrogen energy.

Hydrogen embrittlement is a phenomenon that occurs when hydrogen atoms are absorbed into metals, reducing the toughness and strength of the metal. Shimadzu's analytical instruments are useful for testing the strength of materials such as pipes and tanks used for transporting and storing liquid hydrogen and hydrogen gas, and for checking the degree of corrosion using X-ray CT.

There are various methods for producing hydrogen, such as steam reforming and water electrolysis, but catalysts play an important role in improving efficiency and reducing costs in all methods. Therefore, it is important to evaluate catalyst performance and check the degree of deterioration. Catalysts involved in hydrogen production are often made of metals such as platinum and palladium, and Shimadzu's various instruments are useful for analyzing these metals. Performance evaluation can be performed using CGT, and confirmation of the degree of deterioration and analysis of the cause of deterioration can be performed using EPMA or XPS.

FCVs are equipped with hydrogen tanks. In-vehicle high-pressure hydrogen tanks can store more hydrogen by increasing the hydrogen storage and compression pressures, thereby extending the cruising range of FCV vehicles. It is important for hydrogen tanks for FCVs to be airtight, heat resistant, pressure resistant, lightweight, compact, and low cost. Hydrogen tanks currently manufactured use materials such as resin liners, carbon fiber reinforced plastics (CFRP), and glass reinforced plastics to meet the above requirements. Universal testing machines, thermomechanical analyzers, etc. are effective in understanding the characteristics of each material. In addition, X-ray CT and Ultrasonic Optical Flaw Detector are useful for observing cracks and voids in hydrogen tanks.