Tensile Tests of Rubber Dumb-bell Specimens

Tensile Tests of Rubber Dumb-bell Specimens 【Standard No. ISO37: 2005 (JIS K6251: 2010)】

Introduction

Rubber materials have characteristic mechanical properties including elasticity and flexibility, and are widely used for industrial parts, construction materials, and housewares. In particular, a diverse range of synthetic rubber materials with differing properties suited to match their application have been developed. Measuring these mechanical properties is extremely important to ensure quality control and for new materials development. This Data Sheet introduces an example of the evaluation of three synthetic rubber (main components: chloroprene [1]; urethane [2]) specimens (dumb-bell test pieces). Static tensile tests were performed, and the specimens were evaluated with respect to tensile strength, stress at given elongation, and elongation at break, which are aspects of their basic mechanical properties.

Measurements and Jigs

In tensile tests of rubber dumb-bell specimens, the grips must tighten automatically. When tensile loads are applied to rubber materials, they elongate and their thickness decreases. For this reason, if there is no automatic tightening mechanism, the specimen will inadvertently break free of the grip before the maximum load is applied, making favorable measurements impossible. Accordingly, in rubber tensile tests, it is necessary to use pneumatic parallel grippers, pantograph grips, eccentric roller type grips, Henry Scott type grips, or other grips equipped with this feature.

Measurement Results

Fig. 1: Test Status

Fig. 2: Relationship Between Stress and Elongation

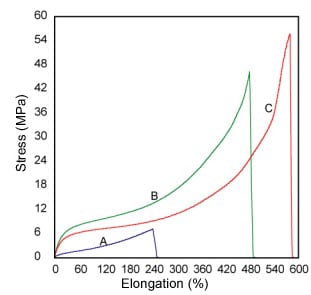

The tensile test results for the three samples are shown in Table 2. A graph showing the stress-elongation relationship for the samples is shown in Fig. 2. Clear differences in mechanical properties such as tensile strength and elongation at break are apparent between the samples.

Rubber (Dumb-bells test pieces) Tensile Test System

| Tester: | AGS-X |

| Load Cell: | 1 kN |

| Test Jig: | 1 kN pneumatic flat grips (Single-side file teeth grip faces) |

| Extensometer: | SES-1000 type extensometer for soft specimens |

| Software: | TRAPEZIUM LITE X |

Features

- A high-precision load cell is adopted. (The high-precision type is class 0.5; the standard-precision type is class 1.)

Accuracy is guaranteed over a wide range, from 1/500 to 1/1 of the load cell capacity. This supports highly reliable test evaluations. - Crosshead speed range

Tests can be performed over a wide range from 0.001 mm/min to 1,000 mm/min. - High-speed sampling

High-speed sampling, as fast as 1 msec. - TRAPEZIUMX LITE X operational software

This is simple, highly effective software. - Jog controller (optional)

This allows hand-held control of the crosshead position. Fine position adjustment is possible using the jog dial. - Optional Test Devices

A variety of tests can be conducted by switching between an abundance of jigs in the lineup.