Evaluation of Functioning of Shape Memory Alloys in Automatic Stress-Strain Control Mode of Shimadzu Autograph

Shape memory alloys, drawing keen interest for their unique characteristics as metallic materials, are currently used widely in the fields of space exploration, the automobile industry, electronic instruments, medical instruments, and consumer goods. Further study to expand their application is going on.

Change of shape, recovery ratio and recovery force are major factors of the shape memory effect. One area of inquiry of particular interest is how the change of stress and strain is influenced by temperature.

The Shimadzu Autograph, an automatic stress-strain control device, can control loading rate and gauge length strain rate through its computer control system.

The following is an example of function evaluation of shape memory alloys using the Shimadzu Autograph.

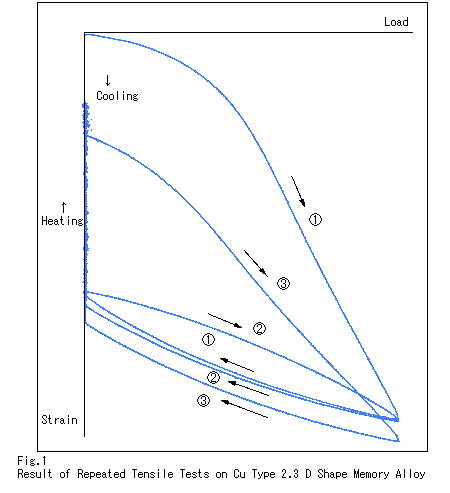

Repeated tensile tests on Cu type 2.3 D shape memory alloys

Test conditions

|

Grip |

: |

Constant position type 5-ton grip |

|

Loading rate |

: |

1.5 kgf/sec |

|

Load range |

: |

100kgf/full scale |

Load-strain curves and results of data processing of the tests conducted under the test conditions given above are shown in Fig.1.

An apparent residual strain of 1.9% occurred when a tensile load of max. 95 kgf (produced strain was approx. 2.58%) was applied and then unloaded to zero. When the second load was again applied at this state, no plastic strain was observed.

A residual strain of approx. 2.0% occurred when unloaded again.

When the specimen was heated at this state with no load, the residual strain was reduced to approx. 0.5% due to the shape memory effect.

When heating was stopped, the reduced residual strain began to increase as the temperature momentarily rose.

It is known from this test that the shape memory alloy responds to heating and cooling with a bilateral shape memory effect.

When the third tensile load was applied again, the same load-strain curve as that of the first was produced, showing that it recovered its original state.

By using the automatic load-strain control device of the Shimadzu Autograph, a constant load test can be exercised with the result of representing shape recovery characteristics in terms of recovery strain data.

In addition, hysteresis energy can also be calculated by processing the data of load-strain curves for another evaluation of the shape memory function.