Static Tensile Strength Testing for CFRP

Static Tensile Strength Testing for CFRP

In recent years, analyzing structural damage utilizing FEM (finite element method) analysis and other techniques has been used in product design in order to shorten the product development cycle, reduce prototype costs, and reduce the cost of strength testing of components. To improve the accuracy of damage analysis, the necessity of evaluating the correlation between actual tests and analysis results will be heightened. A strong demand is also anticipated for so-called solutions technologies capable of evaluating the breakage behavior of components and visualizing in-plane strain distributions, phenomena that are difficult to measure with existing techniques. Introduced below is the attainment of DIC analysis in high-speed tensile tests using the HPV-X system, which satisfies the requirements of imaging speed and resolution.

CFRP

CFRP (carbon-fiber reinforced plastics) and other fiber reinforced composite materials are characterized by remarkable strength and lightness, and are widely used as a material for aircraft parts. Their subsequent expanded application in automobiles and a variety of other products is expected. With CFRP, it is known that breakage progresses with the damaged area as the starting point, and when the maximum test force is reached, high-speed brittle fracture is seen. Clarifying the details of this breakage process is extremely important to the construction of damage analysis models.

■ Test Example

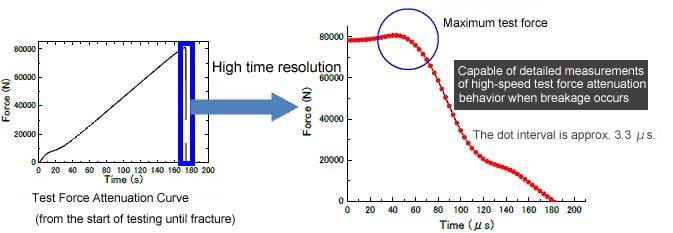

Static Tensile Strength, High-Speed Sampling 300kHz (Test Speed 5mm/min)

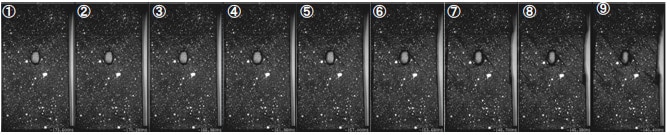

Static Breakage Observations (video recording speed: 300,000 frames/sec, imaging interval: 3 μs)

Cracks occurring in the vicinity of circular holes spread out along the layer at 45 degrees to the surface.

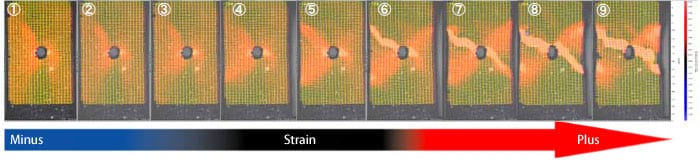

DIC Analysis

The strain is focused not only on the 45℃ direction, but also on the -45℃ direction.

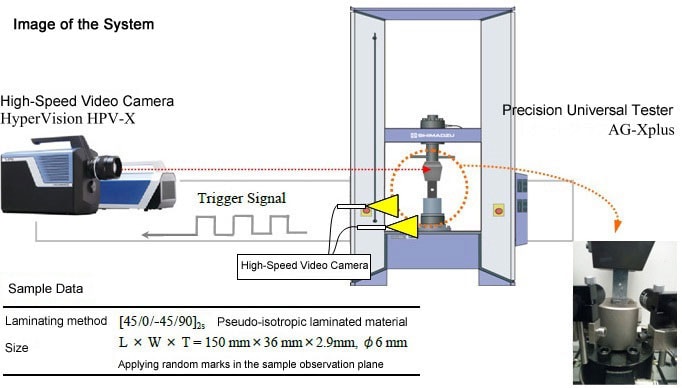

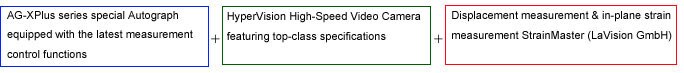

System Overview

High-Speed Breakage Observation System

Sampling test force data at 300 kHz

Capable of saving 2,000 data points at 300 kHz at the time of breakage

Capable of detecting fractures reliably

Fracture is detected with a load amplifier, and the trigger signal is transferred to the high-speed video camera.

Breakage of the material is precisely observed by high-speed video recording.

Synchronized with the HyperVision high-speed video camera

The process of material breakage can be clarified through observations in the high time resolution region

DIC analysis System

Breakage of the material is precisely observed by high-speed video recording.

Synchronized with the HyperVision high-speed video camera.

The process of material breakage can be clarified through observations in the high time resolution region.

Displacement measurement & in-plane strain measurement

Displacement measurement and the two-dimensional strain mapping can be done based on image data from the high-speed video camera.

Non-contact type

Measurements can be performed without affecting the sample.

DIC (digital image correlation)

In this method, a random pattern on the surface of an object is compared before and after the object is deformed, in order to investigate the degree of pattern movement. This method can be used for strain analyses of components under high temperatures, large structures, and microscopic components under a microscope.

High-speed breakage observation system: Developed in conjunction with the Composite Materials Technology Center in the Research and Development Department of the Japan Aerospace Exploration Agency.

Precision Universal Tester AG-Xplus Series

This precision universal tester has been designed for higher reliability and operability, and provides highly controlled measurement performance. It demonstrates superior performance with respect to the three important processes in a tester: settings, measurements, and inspections. Newly developed TRAPEZIUMX, computer software using the latest NET technology, features the utmost in user-friendliness. Also, a color TFT touch panel has been added, enabling test execution without a computer, the direct setting of test conditions created with a computer via a USB memory stick, and retrieval of results. Choose from floor mounted or table-top models to suit your application.

High-Speed Video Camera

Equipped with Shimadzu's proprietary FTCMOS high-speed CMOS image sensor, this camera achieves ultra-high-speed continuous video recording of up to 10,000,000 frames per second. The memory capacity has also been expanded, enabling storage of up to 256 image frames. Furthermore, at up to 5 million frames/second, video can be taken with a maximum resolution of 400 x 250 pixels, enabling detailed analysis of samples.