Carbon Nanotube | Purity | Measurement of Residual Impurities (X-Ray Photoelectron Spectrometer)

Typical methods for producing carbon nanotubes (CNTs) include arc discharge, laser ablation, and chemical vapor deposition (CVD). As each method results in by-products in the CNTs, such as amorphous carbon, carbon nanoparticles, fullerenes, and metal nanoparticles, purification is required after production. Fullerenes are eliminated by extraction as they dissolve in organic solvents. Metal impurities can be eliminated by acid treatment. Trace levels of impurities can remain if purification is inadequate.

X-ray photoelectron spectrometry permits highly sensitive measurements of catalyst elements and impurity elements from the acid used for purification with just 0.1 mg samples.

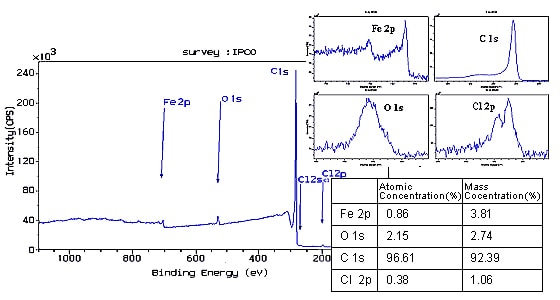

The results of X-ray photoelectron spectrometry measurements of single-walled carbon nanotubes (SWNTs) are shown below.

X-ray photoelectron spectrometry is effective for highly sensitive measurements of catalyst elements and impurity elements from the acid used for purification in CNTs. In this example, iron (Fe) derived from the catalyst and chlorine (Cl) derived from the acid were detected.

This method is thought to be effective for the analysis of the modification group of chemically modified CNTs.

X-ray Photoelectron Spectrometer

The Micro XPS instrument automates the procedures from introducing the sample to starting analysis. The analysis position can be rapidly assigned to any point on the 110 mm-diameter sample platen from a CCD camera image or realtime photoelectron image. The revolutionary, patented neutralization method produces high-resolution spectra with no damage to the sample, thereby allowing micro analysis of organic matter that was conventionally considered difficult.