All You Need To Know About Advanced Plastics Analysis

Measurement of the Compressive Elastic Modulus of Resin Pellets with a Precision Universal Tester Using Trapezium-X

The data obtained for evaluating the strength of materials using a precision universal tester includes tension, compression, bending strength, and the elastic modulus. This report describes an attempt to measure the compressive elastic modulus of resin pellets of a variety of shapes and sizes. Here, the elastic modulus is measured in three ways; (1) provisional elastic modulus measurement including frame deflection without using an external displacement gauge; (2) reliable elastic modulus measurement with a displacement gauge between compression plates; and (3) elastic module measurement using the deflection correction function provided by TRAPEZIUM-X, the materials testing operational software. The elastic modulus is measured between 100 N/mm2 and 150 N/mm2, the linear portion of the stress-strain curve's elasticity region (in the vicinity of the inflexion point). The effectiveness of the deflection correction provided by TRAPEZIUM-X, the materials test operational software, was confirmed by comparing the 3 elastic moduli.

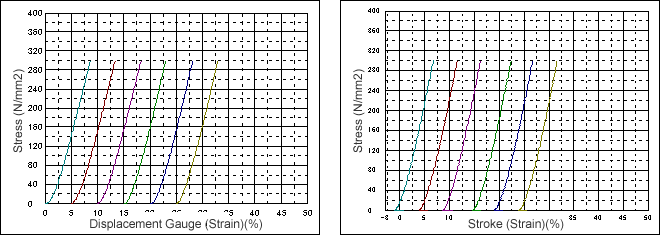

Fig. 1 is a provisional diagram of stress versus strain including the frame deflection, without using an external displacement gauge. Fig. 2 is a diagram of stress versus strain using a displacement gauge between compression plates. Fig. 3 is a diagram of stress versus strain using the deflection correction function of TRAPEZIUM-X, the materials test operational software.

Here the compressive strength measurements were performed at a speed of 1 mm/min, using the Shimadzu Autograph AG-1kNZ and a compression test jig.

As shown in Table 1, the elastic modulus obtained using the deflection correction provided by TRAPEZIUM-X, the materials test software, is comparable to that when deflection has been measured reliably. Further, as shown in Table 2, the elastic modulus can be measured by TRAPEZIUM-X even for samples with comparatively small modulus values.

Table 1 Elastic Modulus Comparison for Resin Pellet 1

| Measurement Method |

Average Value of Elastic Modulus |

| Provisional Elastic Modulus Including Frame Deflection | 3177.02 |

Figure 2:Diagram of Stress Versus Strain Using Displacement Gauge Between Compression Plates

Figure 3:Diagram of Stress Versus Strain Using Deflection Correction

| Elastic Modulus From Displacement Gauge Between Compression Plates |

4259.03 |

| Elastic Modulus From Materials Software Deflection Correction | 4280.66 |

Table 2 Elastic Modulus Comparison for Resin Pellet 2

| Measurement Method |

Average Value of Elastic Modulus |

| Provisional Elastic Modulus Including Frame Deflection | 295.1 |

| Elastic Modulus From Displacement Gauge Between Compression Plates | 302.2 |

| Elastic Modulus From Materials Software Deflection Correction | 302.9 |

From this, values close to the true elastic modulus can be obtained through correction calculations using the Shimadzu Autograph AG-1kNZ and TRAPEZIUM-X materials test software, even when measurement of the actual sample deformation is difficult.