All You Need To Know About Advanced Plastics Analysis

Breaking Strain Measurement of ABS Resin

Increasingly high performance engineering resins are being developed for use in a wide range of fields, such as the automotive industry, consumer electronics, office automation equipment, for their various functional characteristics. Some of the criteria that have become especially important for evaluating the performance of such materials is impact resistance and its associated material properties, such as strength and rigidity. In addition to evaluating materials in terms of conventional static tensile strength, highrate tensile strength, longitudinal elasticity, and strain measurements up to the breakpoint are expected to become important new parameters for materials development. This example describes testing the highrate tensile strength of a flat plate specimen of ABS resin and measuring strain up to the breakpoint. Images of the high-rate tensile test were captured with a high-speed video camera and image analysis software was used to measure the strain between gauge length on the specimen.

Video of High-Rate Tensile Test of ABS Resin

Images of the ABS resin specimen (4 frames) before and after breakpoint during the high-rate tensile test are shown in Fig. 1. In this example, the recording speed was 32 kfps. The interval between frames was 32 microseconds.

Fig. 1 Four Frames of Specimen Before and After Breakpoint

Breaking Strain Measured from Images

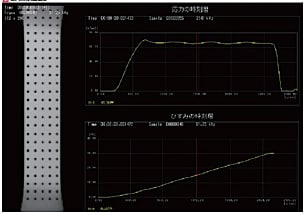

Fig. 2 Video of Tensile Test and Time History of Strain and Stress

A time history of strain between gauge length is determined by using image analysis software to analyze the images obtained. In this case, gauge length was specified longitudinally 30 mm apart on an image of the specimen not moving (16 consecutive dots apart at the center of the specimen), then that gauge length was automatically tracked as a function of time to measure the longitudinal strain. The resulting time history of strain obtained is shown in Fig. 2. In addition, a time history of stress measured by the highrate tensile testing machine or external data logger can be displayed simultaneously as well. Furthermore, images are displayed synchronized with strain and stress in terms of time. This tensile test example resulted in a tensile strength and breaking strain of ABS resin that was 70 MPa and 30 %, respectively.

Determining Stress-Strain Relationship in High-Rate Tensile Test

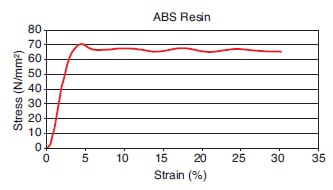

Fig. 3 Stress-Strain Curve up to Breakpoint

Producing a stress-strain curve, which is easy for static tensile testing, is an extremely difficult technical challenge for high-rate tensile testing. Strain gauges can only measure a small range and contact type extensometers do not work for shock. In this example, a stress-strain curve was obtained for ABS resin by synchronizing the video image timing with the test force. A stress-strain curve up to the specimen breakpoint is shown in Fig. 3. In this way, combining a high-rate tensile testing machine, high-rate video camera, and image analysis software, enables simultaneously evaluating high-rate tensile properties, including breaking strain, and visualizing changes in the status of resins.

Tensile Test Specimen Mounted in Grips

Setup of High-Rate Tensile Test and Video Recording

Impact Testing

Puncture Impact Testing (Puncture Test) Mandatory for Impact Evaluation of Resin Materials

[Features]

- Speed can be set arbitrarily up to 72 km/h (20 m/sec).

- The maximum impact force, energy, displacement (deformation) and fracture type, and other test parameters can be easily evaluated and output as graphs.

- Improved test efficiency is also aided by controlled temperature environments (thermostatic chambers), specimen stackers and other options.

- The pneumatically operated specimen retaining mechanism can be easily operated.

- ISO 6603-2, JIS K7211-2 (draft), ASTM D3763 compatible

High-Speed Video Camera

Shimadzu Corporation's High-Speed Video Camera HyperVision HPV-2 offers world-class ultra-high-speed video recording of up to one million frames per second. The HPV-2 permits recording of ultra-high-speed phenomena not previously possible in a wide variety of fields that require high-speed image capture, such as materials failure, fluid dynamics, combustion, and sports science.