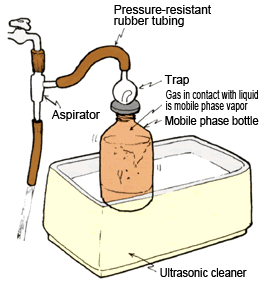

5-2) Vacuum Degassing Using an Aspirator

Vacuum Degassing Using an Aspirator

This method can also be used to quickly remove excess dissolved air.

Procedure

Attach the aspirator to the mouth of the mobile phase bottle and degas by aspirating while vibrating the bottle using an ultrasonic cleaner or agitating the mobile phase. The process is finished when vigorous bubbling of small bubbles stops. If aspirated too much, large bubbles form or the mobile phase boils. During aspiration, since gases in contact with the liquid increasingly are mobile phase vapor (as partial pressure of air approaches zero), the dissolved air content is easily degassed below the saturated solubility level. On the other hand, if the bottle is placed at the pump inlet, the gases in contact with the liquid are gradually replaced by air, so air begins redissolving. Also, during aspiration, the heat of mobile phase vaporization is lost, which allows it to cool easily. In this case, the solution temperature increases after the bottle is placed at the pump inlet and, in contrast to the description earlier, the saturated solubility is likely to decrease.

Fig. 20 Degassing Using an Aspirator

Advantages

- Degassing is quick.

Disadvantages

- Reducing the pressure too much can alter the solvent composition.

- Baselines are prone to drifting for refractometers and some UV detectors.

Applications

- Normal-sensitivity analysis using UV or fluorescence detection. However, back pressure must be applied to the detector if using a column oven, detector cell heating, or a high-pressure gradient.

- Not suitable for high-precision analysis due to likelihood of liquid temperature changes or solvent composition changes.

- If using electric conductivity detection or electrochemical detection with only water as the mobile phase solvent, excessive degassing below the saturated solubility level enables several hours of analysis.