Vacuum System

Overview of Vacuum System

A vacuum system is indispensable to the free flight of ions in a mass analyzer. Two stages of a vacuum pumping system are generally used in MS. The pump in the first stage, called the main pump, evacuate carrier gas from the GC to maintain the interior of the chamber at a high vacuum. In the next stage, the backing pump evacuates the exhaust of the main pump.

Why Does MS Require High Vacuum?

Ions are created in the ion source. However, they may collide with many types of gas, such as carrier gas (He) and residual gas (air, water etc.), on the way to the detector to be unfortunately removed. This collision may happen in a short time with a low vacuum. We call the average distance of an ion's free flight without collision the "mean free path". If a high vacuum provides a long mean free path exceeding the dimension of the chamber, ions can easily reach the detector. QPMS is usually operated at around 10-3 to 10-4 Pa pressure, which corresponds to 5m to 50m of a mean free path.

Turbomolecular Pump

(1) A clean vacuum can be obtained and the background of hydrocarbons is extremely small.

(2) Start-up time / shut-down time is very short.

A turbomolecular pump is a clean vacuum pump suitable as the main pump of a mass spectrometer. The blades of a turbomolecular pump (TMP), rotating with high speed, for example 60,000 RPM, hit gas molecules down and remove gas from the vacuum chamber.

Single Pumping System

A vacuum of a MS is mostly determined by the flow rate of the carrier gas that is flowing into the MS from the GC. Other sources of gas are from desorption of adsorbed gas (water, air) and contamination. The simplest evacuating system is a single pumping system that evacuates the chamber with the one main pump. The vacuum pressure is roughly proportional to the carrier gas flow rate and inverse proportional to the pumping speed of the main pump.

Limitation Factors of Vacuum

Vacuum pressure is limited by the following three factors.

- Carrier gas: Depends on analytical parameters.

- Gas desorption from the surface of the chamber and parts: Decreases slowly. It takes much time for this contribution to decrease.

- Limitation from pump performance. Usually, pressure less than 10-3 to 10-4 Pa is required near the rod and the detector

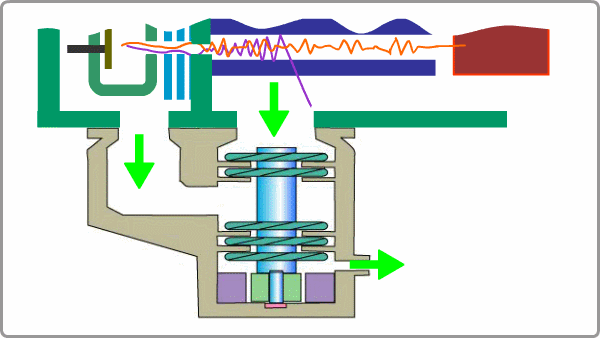

Differential Pumping System

A single pumping system would require the main pump with the 5 times larger pumping speed if the flow rate of carrier gas is 5 times larger. But only adding a small main pump provides a suitable vacuum for GC/MS analysis with even a high flow rate if a differential pumping system is applied to the MS. In this system, a wall with a small hall for ion passage divides the vacuum chamber into the ion source cell and the QP rod-detector cell. Each cell is evacuated with the different pump. This hall limits the inflow of carrier gas so that the higher vacuum is achievable in the QP rod-detector cell.

Single Pumping System and Differential Pumping System

When we compare a differential pumping system to a single pumping system, a vacuum in the vicinity of the MS analyzer and detector is about 5 to 10 times better for a differential system than the single system. In cases where we use the performance of a TMP for a single pumping system and the ion source side of differential pumping system, we can afford to flow more amount of carrier gas into the MS.

Dual Inlet Turbomolecular Pump

Some GC/MS systems use a split-flow TMP for the differential pumping system shown in the figure. A Splitflow Turbomolecular pump that has two vacuum inlets is a suitable TMP for a differential pumped mass spectrometer.

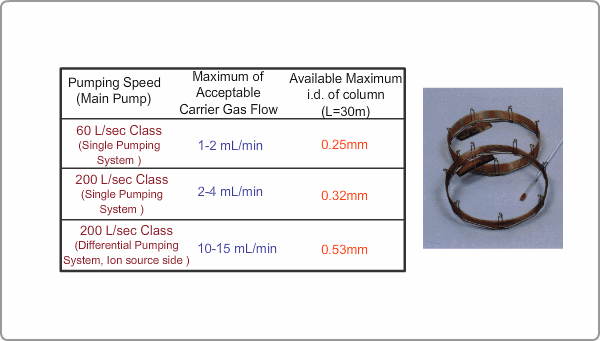

TMP Pumping System and Column

The internal diameter and length of a column affects vacuum pressure. Using the column of larger internal diameter makes carrier gas flow larger and requires a more powerful and more effective evacuating system. The table shows a rough estimate between the pumping capability and the column limitation from the view of the vacuum.