Films and Plastics

■ Introduction

So-called plastics are available in a variety of forms including powders, films, and sheet. They can be molded into products and a molded product can contain many types of polymer material.

A variety of FTIR infrared spectroscopy methods are available to measure plastics according to their forms and measurement positions. The following introduces these measurement methods.

■ Measurements by Transmission Methods

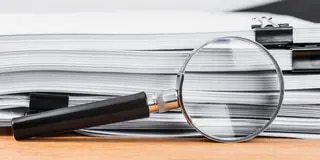

Fig. 1 Transmission Spectrum of Polystyrene Film

Transmission measurements can be performed on a monolayer film up to 40 to 50 µm thick or on a film of equivalent thickness produced by the film method, by holding the sample in a suitable holder, such as thick paper. These measurements are extremely simple but can often be affected by interference fringes, as shown in Fig. 1. Such interference fringes can be exploited to measure the film thickness but they hinder the use of the spectrum for quantitation or qualification. These effects can be reduced by roughing the film surface with sandpaper.

The film method involves dissolving a sample in a solvent, spreading the solution thinly on a glass or metal plate, and allowing the solvent to evaporate to create a film of the sample.

■ Attenuated Total Reflection (ATR) Method

ATR spectroscopy is an effective measurement method for thick film, plastic, or rubber samples that do not transmit infrared light.

For ATR spectroscopy, the sample is pressed into close contact with a prism. During total internal reflection of the infrared light in the prism, a small amount of the infrared light enters the sample, enabling an infrared spectrum to be obtained. As the penetration depth is just a few µm, this method obtains information only from the sample surface. Therefore, it can directly measure thick film or plastic samples which do not transmit infrared light. Also, the penetration depth can be altered by changing the angle of incidence of the infrared light and the type of prism to obtain information on samples that change in the depth direction. Furthermore, in combination with difference spectra, this method can obtain spectra for different internal layers of a multilayer film.

■ Specular Reflection Method

If the sample surface is relatively flat and smooth, the specular reflection method can be used to obtain the infrared spectrum. If the SRM-8000 specular reflectance accessory is used, the sample is simply positioned with the measured surface facing downward. The method is simple and requires no effort to force the sample against a prism, as with ATR spectroscopy.

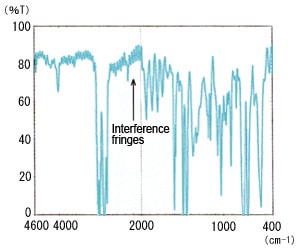

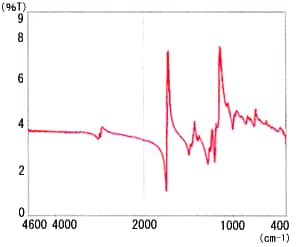

However, if this method is used to measure a sample such as plastic sheet, the reflectance is just a few percent and peak distortion occurs, as shown in Fig. 2. Such peak distortions result from the anomalous dispersion of the refractive index and it is extremely difficult to use such spectra either qualitatively or quantitatively. For this reason, Kramers-Kronig conversion must be applied to a distorted spectrum to obtain a normal absorption spectrum. Fig. 3 shows the spectrum in Fig. 2 after Kramers-Kronig conversion.

Fig. 2 Specular Reflectance Spectrum for Polymethyl Methacrylate (PMMA)

Fig. 3 Spectrum After Kramers-Kronig Conversion

■ Infrared Microscope Measurements

An infrared microscope is effective for measuring the infrared spectrum of each layer of a multilayer film.

If an infrared microscope is not used, the individual layers must be separated and transmission spectroscopy performed on each layer. Also, if the individual layers are stuck together with an adhesive, the adhesive must be completely removed.

Conversely, as the infrared microscope can measure minute areas approximately 10 µm in size, a multilayer film can be thinly sliced into cross-sections with a microtome and the individual layers measured.

■ SiC Sampler

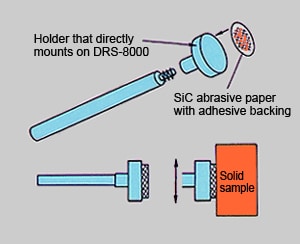

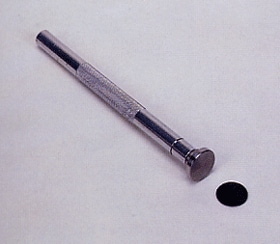

The methods described above presuppose that the sample size is suitable for measurement or that the sample can be cut to a size suitable for measurement. However, not all samples meet these conditions: for example, a plastic tank in use. Obtaining the infrared spectrum for such a large molded product demands a certain amount of effort for sampling and pretreatment. Also, in some cases it is not possible to excise a sample. The SiC sampler is an extremely effective and convenient sampling method in such situations. The SiC sampler scrapes off the sample with silicon-carbide (SiC) sandpaper attached to a holder. The sample is collected directly on the sandpaper. The infrared spectrum is measured by mounting the holder in the diffuse reflectance accessory. This simplifies the analysis of large molded parts and saves the effort for pretreatment, such as excising and diluting the sample.

Fig. 4 Construction of the SiC Sampler

Fig. 5 Appearance of the SiC Sampler

■ Conclusions

Here we discussed the measurement methods for plastics. When plastics are measured, the appropriate measurement method must be selected according to the sample form and the purpose of the analysis.