Higher Speed

Acetonitrile is generally used as a mobile phase because there are fewer obstructions in the short wavelength region in UV detection.

However, there is a shortage of acetonitrile. To greatly reduce the solvent consumption, we would like to introduce a high-speed analysis for reducing analysis time and conserving acetonitrile.

Shortening Analysis Time by Speeding up Analysis

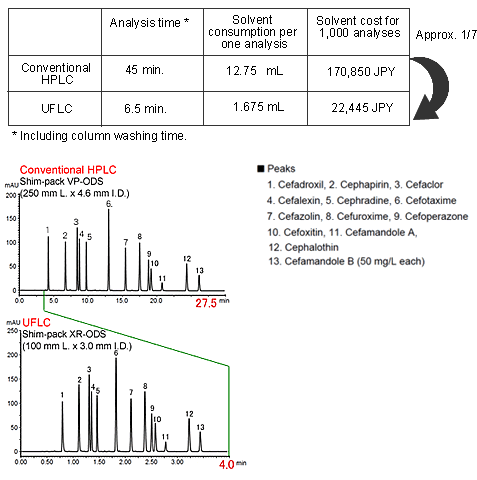

How much analysis time can an ultra high-speed analysis save? For example, regarding analysis of 12 substances of cephem antibiotics, it takes 27.5 min. with conventional LC. UFLC (Ultra Fast LC) can shorten the time to 4 min. This example demonstrates that the migration to high-speed analysis provides a reduction of solvent use to about 1/7. When multiple samples are analyzed continuously, where it previously might have required 3 L of mobile phase, barely 500 mL is sufficient, indicating the great reduction in solvent consumption and discharge.

So, how can we realize an ultra high-speed analysis?

To shorten the time required to complete an analysis, the speed must be increased. That concept is simple, and can be achieved by replacing the column with one having smaller dimensions (length, inner diameter), or increasing the flow rate of the solvent delivery pump.

Shortening the analysis time can only be considered successful if:

(1) the peaks of interest are all eluted.

(2) analyte peak separation is maintained.

If simply a column having small dimensions is used, or the flow rate is increased, higher speed may be achieved, but peak separation will be sacrificed due to the insufficient time the sample will have to interact with the column packing. How can we keep the analysis speed without degradation of peak separation?

What is an ideal high-speed analysis?

To control the deterioration of peak separation while maintaining higher speed, a column packing with smaller diameter particle size is adopted. According to the van Deemter equation, this is because use of very fine column packing material controls the deterioration of resolution which occurs when the flow rate is increased and the column is shortened.

According to this equation, the finer these particles are made, the greater the resolution will become from a theoretical standpoint.

However, from a practical standpoint, deviation from the van Deemter equation occurs due to various factors including column packing particles becoming too small.

For example, if the particles become too fine, the spacing within the packing material becomes so small that the pressure increases dramatically, even under the normal flow rate conditions. This leads to increased frictional heat between the mobile phase and column packing material, resulting in irregular temperature in the column. This can lead to broadened peaks and deterioration of resolution. Thus, an ideal high-speed analysis cannot be achieved by decreasing the particle size diameter indefinitely due to high pressure imposed on the system.

The Prominence UFLC,in combination with theXR-ODS seriesof columns, is equipped with a function to realize ultra high-speed analysis with suppressing the dissociation of the van Deemter equation.

Migration to High-Speed Analysis

The software for migrating the analytical method for normal analysis to that for high-speed analysis is offered free of charge from Shimadzu. With this program, after entering the current analytical conditions and any other specific requirements, just pressing the “Optimize” button allows selection of the appropriate column and calculation of the high-speed analytical conditions.

After some points are understood, ultra high-speed analysis is available using the normal HPLC system and Shim-pack XR-ODS.

To conduct ultra high-speed LC/MS analysis, a mass spectrometer that can follow the high-speed analysis of LC is needed. TheLCMS-2020catches various peaks, which are output by Prominence UFLC, and strongly supports the migration to ultra high-speed LC/MS analysis form normal HPLC.

We are preparing the details of “Reduced Solvent Consumption and Operational Costs with Ultra High Speed Analysis” in Technical Report No. 24. Please contact your Shimadzu local representative for details.