Use of a Semi-micro Column

Principle of Operation

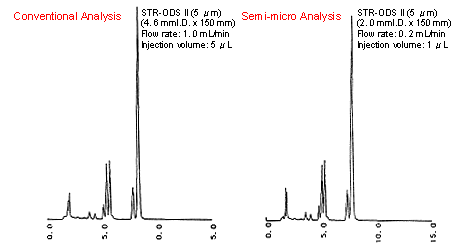

Use of a column with a small inner diameter filled with the same packing material reduces the amount of mobile phase consumption proportionally to the cross-sectional area (I.D.2) of the column. Here, let's assume that samples of the same mass are injected into a semi-micro column of I.D. 2 mm and length 150 mm and into a conventional column of the same length but with an I.D. of 4.6 mm. If the mobile phase linear velocities are set the same (in the figures below, 1.0 mL/min and 0.2 mL/min), the component elution position (i.e. retention time) will be the same since the column lengths are the same, and the amount of mobile phase consumption can be reduced to one fifth. This is called "semi-micro LC."

Advantages

Recent lineups of columns often include both a 4.6 mm I.D. column and a 2 mm I.D. column. An advantage of using a semi-micro column is that a similar chromatogram can be obtained with high probability since separation selectivity is basically about the same.

(though patterns, etc. may vary since the filling method differs slightly).

Precautions

With semi-micro LC, caution is required to obtain the same analysis results as those obtained by a conventional column.

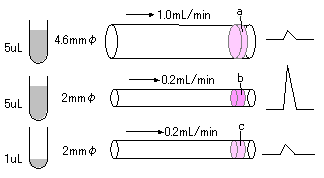

If the stationary phase packing material is the same, the width of the component bands (a and b in figure on right) at the column eluting section are the same since dispersion of the sample in the mobile phase flow direction is about the same. Because the cross-sectional area of b is one fifth of a, the concentration of sample component passing through the cell is 5X corresponding to the mobile phase flow rate ratio between both columns; in other words, the response increases five-fold. This is called "mass sensitivity," and increases the smaller the column I.D. becomes. The effect of this, however, is based on the assumption that the sample injection volume can be ignored. Since the injection volume actually influences the response, the injection volume must be reduced proportionally to the cross-sectional area of the column to simply obtain the same chromatogram. In the examples (a and c) in the figure, the sample injection volume becomes one fifth since the cross-sectional area is reduced to one fifth, with response eventually becoming equal. This is called "concentration sensitivity," and is a fixed value regardless of the column I.D.

With a semi-micro LC, piping having a small I.D. matched to the cross-sectional area of the column is used on the flow path to suppress extra-column dispersion, as described later. Though a smaller flow cell in the UV detector is more appropriate, absorption response is decreased since the optical path length is shorter or the cross-sectional area of the optical path is smaller, which reduces the light intensity. Normally, the noise level hardly changes, but sensitivity might be lowered.

Restrictions

On the other hand, it is important to suppress the influence of extra-column dispersion caused by piping or other factors.

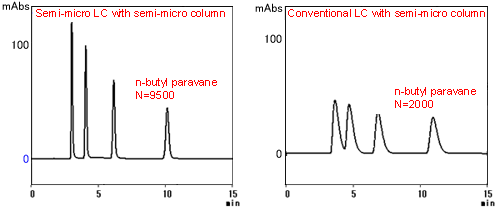

The figures below show examples of analysis performed on p-hydroxybenzoic acid 4 alkyl ester components in a semi-micro LC system/conventional LC system (including a UV detector cell) plus semi-micro column combination. On the conventional LC system, you can see that the volume of extra-column dispersion is too large compared to the column size and that the number of theoretical plates had dropped significantly.

| Piping I.D. | 0.3 mm -> 0.13 mm | |

|---|---|---|

| Gradient mixer | 0.5 mL (standard smallest) -> 100 µL (semi-micro mixer) | |

| Detector cell | 8 µL (standard smallest) -> 2.5 µL (semi-micro cell) | |

When a semi-micro column is used, use smaller-sized piping and detector cell on the flow path matched to the inner diameter of the column to suppress extra-column dispersion. Also, use a smaller gradient mixer matched to the overall reduced size of the flow path. For auto-samplers, give consideration to the piping I.D. at sections where sample passes through. (On the SIL-20A series, SIL-10ADVp and SIL-HT, the recommended piping internal diameter is 0.13 mm.)

Also, compared with conventional LC, the delivery unit is required to have more stable delivery (e.g. accurate flow rate and precision) in the low flow rate region, and the auto-sampler is required to have injection repeatability during injection of minute amount of samples.

The Prominence series satisfies these basic performance requirements. Since the influence of carryover becomes relatively larger, it is preferred that an auto-sampler, such as the SIL-20A on which measures for reducing cross contamination (e.g. with respect to direction injection method, needle surface material, needle washing, valve materials) are implemented, is used.

By using a semi-micro column, major savings in solvent consumption can be expected if the existing LC system can accommodate low flowrate solvent delivery and injection of small sample amounts.