Beware of Static Electricity Generated by Flowing Liquids

Static electricity is experienced during seasons when the air is dry. The crackle sound that occurs when removing a sweater is from the static electricity generated by friction between clothing materials. Similarly, the slight pain sensation experienced when touching a door knob after walking on carpet is due to the static electricity, which was built up in the body from rubbing the carpet, being discharged across the small gap between the door knob and your hand.

Such experiences with static electricity can be relatively common occurrences, so we often don't pay much attention to them in our daily lives.

However, static electricity can be a big problem for electronic parts. At a few kilovolts, our bodies only experience a slight pain sensation (assuming a very slight current level), but some electronic parts can be ruined by only 0.1 kV.

Countermeasures for static electricity are included in the analytical instruments themselves, but larger amounts of static electricity could cause them to malfunction.

Furthermore, some laboratory instruments, such as HPLC (high performance liquid chromatograph) systems, which use flammable organic solvents, require being especially careful due to the risk of fire.

In addition, because it is difficult to understand the mechanism of how static electricity accidents occur, and because some aspects that lead to static electricity accidents only occur when several factors coincide, caution is often ignored. Nevertheless, particular caution is especially required when using large amounts of solvent, because if an accident does occur, it can cause a great deal of damage.

This page specifically describes HPLC effluents flowing into liquid waste containers, but the danger also applies to non-HPLC situations where a solvent with low conductivity flows into a container with low conductivity.

• The Possibility of Accidents from Static Electricity Generated by Flowing Liquid

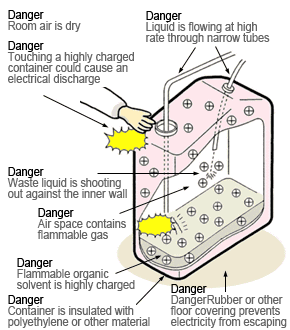

Static electricity generated near the HPLC outflow into a liquid waste container could potentially cause an accident. The process is described below.

1. Generation of Static Electricity

When liquid is passed through thin tubing at a high flowrate, as it is in HPLC systems, the electrostatic charge of the flowing matter generates static electricity (flow electrification). (The charge level is higher for poorly conductive solvents flowing through plastic tubes. In addition, large amounts of air bubbles flowing through the tube can amplify the static electricity.

A: Charge that moves along with liquid flow

B: Charge that is fixed to a solid surface and cannot move

Generation of Static Electricity by a Liquid Flowing over a Solid

2. Accumulation of Static Electric Charge

If electrostatically charged liquid accumulates in an electrically insulated container, the amount of charge gradually increases to a point where it can easily generate high voltages, on the order of several kV.

3. Release of Energy Through Electrical Discharge

If an electrical conductor comes within a certain distance of the container, an electrical discharge occurs, which releases thermal energy.

4. Ignition of Flammable Substances

If there is a sufficient concentration of flammable gas in the surrounding atmosphere, the gas is more easily ignited.

Figure 2 illustrates potential accident situations.

Situations with Danger of a Static Electricity Accident

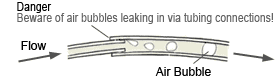

Intake of Air Bubbles Increases Static Electricity

• Preventing Static-Electricity Accidents

To prevent static electricity accidents, measures should focus on preventing the generation and accumulation of static electricity. In addition, to further ensure that accidents are prevented, it is important to implement multiple prevention measures simultaneously. In particular, the following measures should be taken if large amounts of flammable solvents are used.

Measure 1

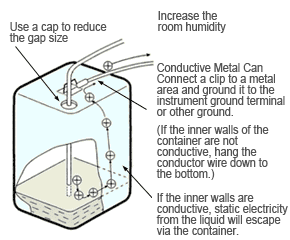

Use a metal liquid waste container (with a conductive interior surface, such as a plated metal can) and connect the container to ground.

Properly ground liquid waste containers. There is no point in using a metal container if it is not grounded or the ground wire becomes disconnected. (P/N 228-21353-91 can also be used as a ground wire.) This ensures that static charge does not accumulate in the waste liquid or the container.

Even some metal containers have surfaces that are oxide-coated or laminated and, therefore, may not be conductive. Use an electrical tester to confirm that the container is grounded. If only liquid with a very low conductivity (10-10 S/m or less) is discharged into the waste container, one method is to add a safe conductive liquid to the container.

Configuration with Measures to Prevent Static Electricity Implemented

Measure 2

To prevent sparks from entering the waste container, keep the size of any gaps at inlet and outlet openings as small as possible.

(To minimize such gaps, P/N 228-21354-91 caps can also be used for 18 L and 4 L cans.)

Measure 3

Keep electrostatically charged objects, including human bodies, away from the waste container.

To prevent the body from becoming charged, wear anti-static clothing or shoes, ground the body using an anti-static wrist strap (with a 1 MΩ resistor to protect the body), or provide conductive floor surfaces in work areas, such as with anti-static floor mats. If you have not taken any anti-static measures, touch a grounded metal object before approaching the waste container in order to ground any electrostatic charge from your body.

Measure 4

Use tubing with a larger inner diameter (at least 2 mm, for example) for drain lines through which large amounts of liquid flow.

Air bubbles in the liquid can increase electrostatic charge by a factor of several tens. Check the tubing connections for air leaks.

Measure 5

If the liquid waste container cannot be made conductive, make sure the end of the drain tube remains below the surface of the liquid in the waste container. Alternatively, place grounded metal in the liquid.

However, this method is mostly ineffective for liquids with low conductivity (10-10 S/m or less).

Measure 6

Use a liquid waste container that is as small as possible to minimize the damage in the event of a fire.

Measure 7

Increasing the humidity level (above 65 %, for example) can have an anti-static effect. Therefore, do not let the room become dry.

Static electricity accidents can be prevented by observing the measures indicated above. These measures may seem like an unnecessary bother, but being prepared for such possibilities is also important.

As a manufacturer of HPLC systems, we hope to supply easy-to-use peripheral products that are carefully designed for safety as well.

Additional Remarks There are many other areas of the laboratory, besides the HPLC system, that require particular caution regarding static electricity.

1.Flammables: Laboratories contain many flammable substances, such as organic solvents. Keep flammable substances covered to prevent exposure. Provide ventilation for flammable vapors. (Select the height of ventilation fans based on most solvents being heavier than air, but hydrogen being lighter than air).

2.Electrical System: Circuit boards are especially vulnerable to static electricity. In particular, if a statically charged person touches an electrical device with a metal tool, it can cause a malfunction or an instantaneous power interruption. Form a habit of touching the building or water pipes to eliminate any static charge before touching an electrical device.

3.Powders: Powders can cling or jump about due to static from friction with the container or from taking on the static charge from humans. When weighing powders, an ionizer can be used to eliminate static electricity.

→ STABLO Ionizers

In general, the first measure should be to increase the humidity in the room. Another measure is to step on an anti-static mat before entering the room.