Measurement Time and Monitoring Function

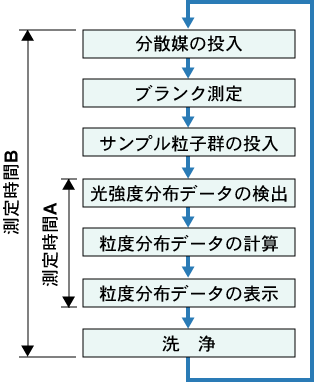

Even with just wet measurement, there are two ways of considering the measurement time on laser diffraction particle size analyzers, as shown in Fig. 1.

Normally, the measurement time listed in catalogs and other literature is "Measurement time A," or the time from "Detection of light intensity distribution data" up to "Display of particle size distribution data" after passing through "Calculation of particle size distribution data." However, if you attempt to measure many samples in a short time, "Measurement time B" from "Loading of dispersion medium" up to "Rinsing" is more problematic. This "Measurement time B" is generally expressed in the form "xx minutes xx seconds including rinsing."

Fig. 1

About ten years ago, it took at least 3 minutes for "Calculation of particle size distribution data" because of the low throughput of the computer or CPU used. This measurement time was once said to be "enough to have a cup of coffee and get back in time for measurement to end." However, now, since amazing advances have been made in the computer and CPU processing speeds, calculation ends in under 0.1 seconds even if pretty complex algorithms are adopted for calculation. Also, the time required for "Display of particle size distribution data" can almost be ignored.

Shortly, this means that "Measurement time A" is basically the time required for "Detection of light intensity distribution data." On analyzers that use two or more light sources, the light source needs to be switched, since the sample particle group should not be allowed to be irradiated with light (not always a laser beam) simultaneously from these multiple light sources. This means that detection takes slightly longer. Especially when light sources are switched by a mechanical shutter or similar mechanism, it takes a fairly long time.

When a single laser light source method is adopted, switching of the light sources is not required and so the detection time is proportionately shorter. (All of the SALD Series models use this method.)

Also, the more sensing elements there are in the sensor, the longer the time required for A/D conversion becomes, though this is not such a big problem compared with the time required for switching the light source.

Actually, although the light intensity distribution data is detected many times and the light intensity detected by each sensing element is averaged, analyzers that use only a single light source can repeat measurement continuously at intervals of about 2 seconds or less if the number of averaging is decreased to a certain extent. Of course, the same is possible even on analyzers that use two or more light sources if only one light source is used. Continuous measurement over many times is almost meaningless when the sample particle group does not change at all. Yet, temporal changes, if any, of the sample particle group in the cell can be monitored. In a sense, I think that this is revolutionary in particle size analyzers. The measurement time (measurement time A) on many particle size analyzers used to be several tens of seconds to several minutes up to several tens of minutes, and could not be used at all for monitoring. So, it can be said that this fact has become a major feature of current (latest) laser diffraction particle size analyzers.

Ok, then. The problem here is whether there exist applications that need to monitor temporal changes of the particle group in a cell (in particular, a batch cell).

Currently, the measurement lower limit of laser diffraction particle size analyzers has fallen to the several tens of nanometer range. If particle size distribution in this region can be measured by a single light source, there is the possibility that the progress of protein antigen-antibody reactions, for example, can be monitored as a relative change in particle size. Also, if the phenomenon occurs where particles precipitate in a cell, then there is also the possibility that this can be monitored.

On the other hand, with "Measurement time B," the time needed for rinsing has not become that much shorter and 3 to 5 minutes are normally required in spite of the fact that "Measurement time A" has been shortened now due to the amazing advances made in computer and CPU throughput. To shorten the measurement time in this case, measures must be devised in the liquid medium supply or rinse methods used in circulation measurement, where a sampler and flow cell are used.

On the SALD-3100 high-speed wet measurement system, a time of 30 seconds has been achieved for "Measurement time B" by using an acyclic motion sampler system.

In other words, numerous samples can be continuously measured at 30-second cycles.