Dry Measurement

Laser diffraction particle size analyzers support dry measurement whereby the target particle group is dispersed in air and measured. The capability for dry measurement in addition to wet measurement, whereby the particle group is dispersed in a liquid, is an important feature of laser diffraction particle size analyzers and suggests the potential for a wide range of applications.

Dry measurement is used for measurement targets and purposes such as follows that cannot be met by wet measurement.

- Drugs and foods that cannot be measured by wet measurement due to their dissolving in water or dispersion medium

- Samples, such as powder paints, that should be measured by dry measurement in consideration of their purpose and conditions of use

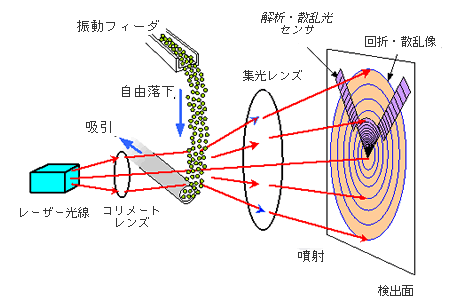

There are two types of dry measurement, injection type (forced-dispersion) dry measurement and free-fall type (Non dispersive) dry measurement. Fig. 1 shows the basic configuration of injection type dry measurement.

Fig. 1 Injection Type Dry Measurement

With the injection type dry measurement method, compressed air is used to inject the measurement target powder (particle group) from a nozzle and forcibly disperse it in air so that it passes through a laser beam for measurement. The dispersing force can be adjusted by the pressure of the compressed air and the shape/structure of the nozzle. With injection type dry measurement, aggregates can be dispersed, which makes it ideal for measurement of primary particles. However, it is generally believed that particles of size 1 µm or smaller hardly exist when a sample is dispersed by this kind of method.

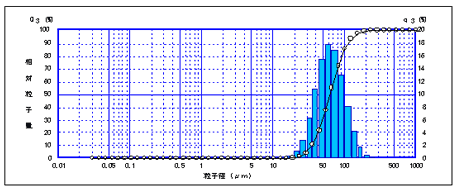

Moreover, by this method, magnetic particles that tend to aggregate in liquid and are more difficult to measure sometimes can be measured successfully. Fig. 2 shows an example of measurement of magnetic particles. Next, Fig. 3 shows the basic configuration of free-fall type dry measurement.

Fig. 2 Measurement Result of Magnetic Particles by Injection Type Dry Measurement

Fig. 3 Free-Fall Type Dry Measurement

With free-fall type dry measurement, as its name implies, measurement target powder (particle group) is made to free-fall by means of a vibrating feeder or similar mechanism from the top of the measuring unit so that it passes through a laser beam for measurement. By this method, powder (particle group) is measured without dispersing force being applied to it. Consequently, this method is suited to powders such as granules that are best not subjected to dispersing force.

Since particles are measured without being dispersed, the size of the particles might become considerably larger compared with the injection type, which necessitates use of an optical system (measuring unit) capable of measuring even large particles.

In the past, wet measurement was the mainstream method in laser diffraction particle size measurement, and fields in which dry measurement was applied were quite limited. Lately, however, use of this latter method has started to rapidly gain popularity mainly in the fields of medicines, pharmaceuticals, foods and paints. Apparently, technological advancements in injection type measurement methods and the capability to measure particle size distribution with high reproducibility just like wet measurement have greatly affected this increasing popularity.