Utilization of Diffracted/Scattered Light Intensity Distribution Data

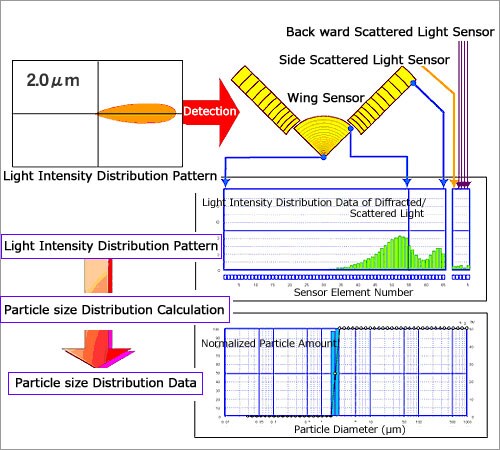

In particle size distribution measurement using the laser diffraction/scattering method, the raw data to be actually detected is the light intensity distribution data (pattern) of the diffracted/scattered light. The particle size distribution is calculated from this light intensity distribution data by calculations. (See the figure below.)

Accordingly, the SALD Series functions as a diffracted/scattered light sensor as well as a particle size analyzer.

The information used for obtaining the particle size distribution is a part of the light intensity distribution data. The light intensity distribution data also includes various physical and chemical information such as particle shape, surface state and refractive index.

Though information other than the particle size distribution data cannot at present be handled quantitatively, the features of patterns can be extracted and qualitatively evaluated.

For example, when pass/fail judgment is made on products made using powders as their raw materials, there are instances where absolutely no differences are observed by looking at the particle size distribution data of the raw material alone but differences are observed in the light intensity distribution data of diffracted/scattered light.

In cases such as this, quality control of the raw material can be conducted using the pattern of the light intensity distribution data even if it is difficult to completely evaluate the raw material quantitatively. Actually, there are many cases where light intensity distribution data is actively used together with particle size distribution data for leading-edge R&D and quality control.