Instrument Validation and Inspection Methods

This page describes instrument validation, an essential process for understanding and managing instrument health.

1. What is Instrument Validation?

Instrument validation is a series of processes performed according to a specified procedure to verify an instrument meets the expected quality standards. This includes recording the validation results as documentation. Because all equipment, instruments, and operating procedures used to ensure the expected product quality need to be periodically checked to identify any problems, validation is required for a wide range of things, from tangible items such as equipment and instruments to intangibles such as operating procedures and manufacturing process steps. This page describes the validation process for UV-VIS spectrophotometers.

2. Information Obtained from Validation

Validation results provide valuable information about the health status of instruments. To properly assess and manage the status of instruments, we recommend validating instruments on a regular basis. It is also important to validate instruments whenever a change occurs in the instrument environment, such as after a consumable was replaced or the installation site was changed.

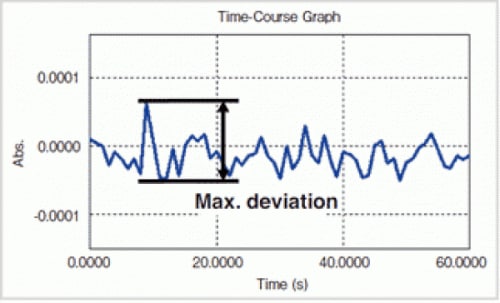

UV-VIS spectrophotometers comprise many parts, some of which are consumables that degrade as a function of time or frequency of use. One example is the light source (lamp), which affects the noise level. Noise level is defined as the maximum absorbance fluctuation range (maximum distance between adjacent peaks and valleys) during one minute of measurements at specific wavelengths with close to zero absorbance. A change in expected noise level provides a clue for determining the status of a lamp. A graph of noise level measurements is shown in Fig. 1.

As the light intensity emitted from a lamp decreases with age, that will result in an increase in the relative magnitude of noise, which results in a higher noise level. A higher noise level means data will have lower reproducibility, which is detrimental to accurately determining photometric values.

If extremely small absorption peaks need to be detected, high noise levels can prevent accurate detection due to the small peaks being buried among the noise. Validation is very important for confirming whether data is being obscured in such a manner.-

Fig. 1 Emission Lines of a Deuterium Lamp

3. Software Assists with Validation

Due to the wide variety of performance parameters that must be checked for instrument validation, it would be very time-consuming to manually check each one. The complicated inspection procedure involved would also be prone to operator errors. To resolve such problems, UV validation software was designed to assist with the measurement and calculation steps required for validation.